All Bases Covered

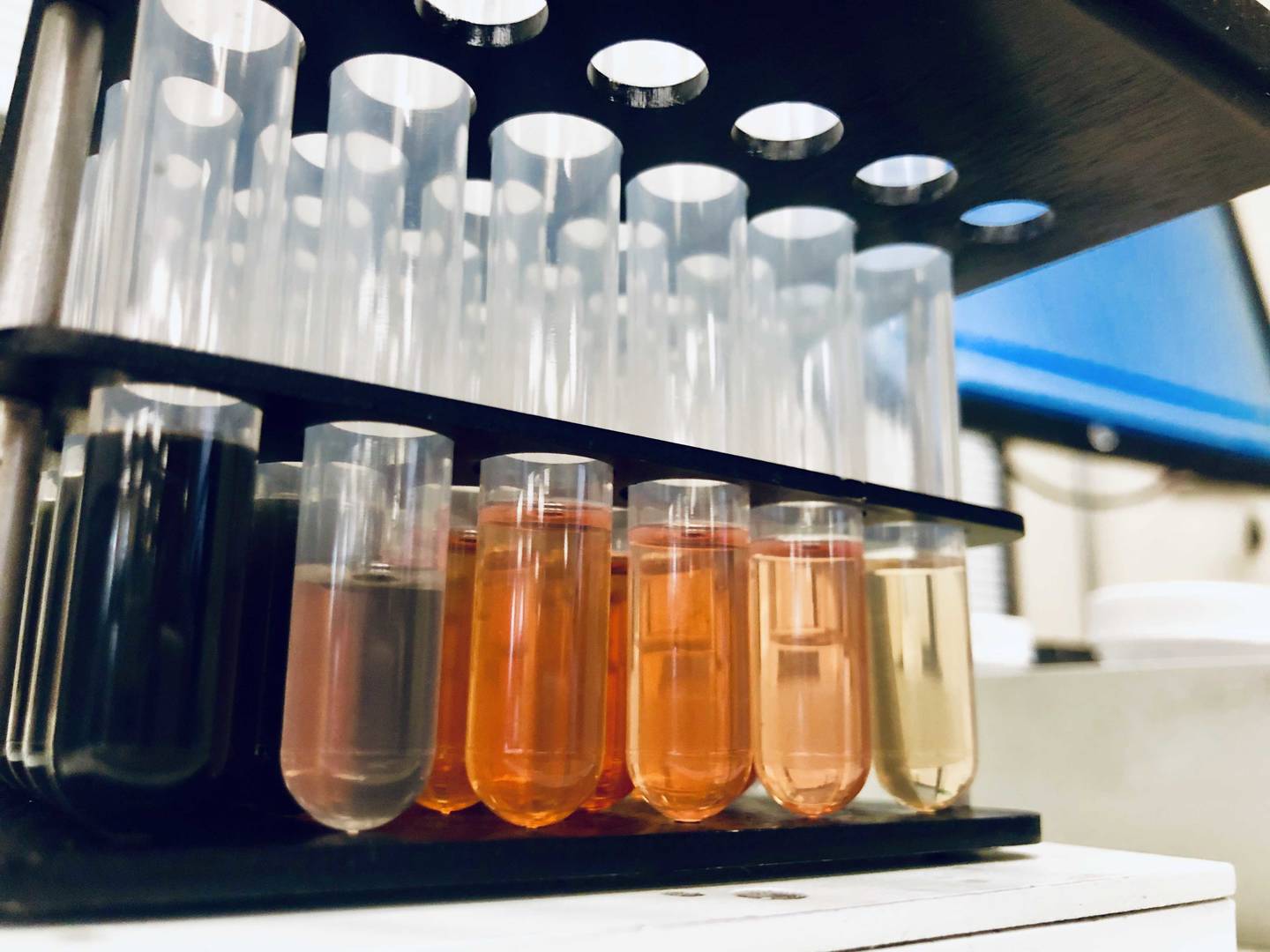

Our Metallurgy Assay Facility covers the vast majority of required analytes for metallurgical testwork. All data are captured from instruments into a custom LIMS and calculations are carried out automatically and sent to the metallurgists allowing for excellent assay turnaround and work efficiency.

Broad areas of services and analysis are as follows:

- Analytical Sample Preparation – The facility houses six automated fully programmable ring pulverising mills. Four are designed to pulverise samples up to 100 g in batches of 60 and the other two take samples up to 1.5 kg in batches of 30. In addition to these automated units, conventional Labtechnics ring mills are still used for both additional capacity and small jobs needing special attention. Jaw crushers, large drying ovens, and rotary splitters are also available.

- Conventional and Classical Assaying – The laboratory is a modern facility offering multiple acid digest techniques combined ICPOES, ICPMS, and AAS finishing instrumentation. Most kinds of classical wet chemistry techniques can be conducted as required.

- XRF Assaying – The laboratory currently runs two sequential XRF instruments. These allow calibrations for a range of sample types. Two semi-automatic electric fusion furnaces give a capacity of at least 600 fusions per 24-hour period. A hand held XRF gun is now available for a limited range of fast on the spot assays (idea for pilot control samples).

- Combustion Furnace Infrared Detection Assaying – The laboratory has two automated carousel CS2000 units for the spectrographic analysis of elements such as sulphur and carbon.

ALS assays undergo QA/QC with every sample submission/batch as a standard practice. Every batch of samples is analysed together with an appropriate proportion of CRM’s (certified reference materials, or standards) and these results are reported in the raw assay results together with the testwork sample results. Detection limits for the requested analytes can be provide on request.

Uncertainty of assay results varies dependent on the level of the analyte. Actual uncertainties, as well as standard results, are recorded for all assay submissions and can be provided if required during the testwork program. If further information required on ALS assay uncertainties and standards, these can be provided on request.

Vyhledat

Vyhledat

čeština

čeština

Login

Login