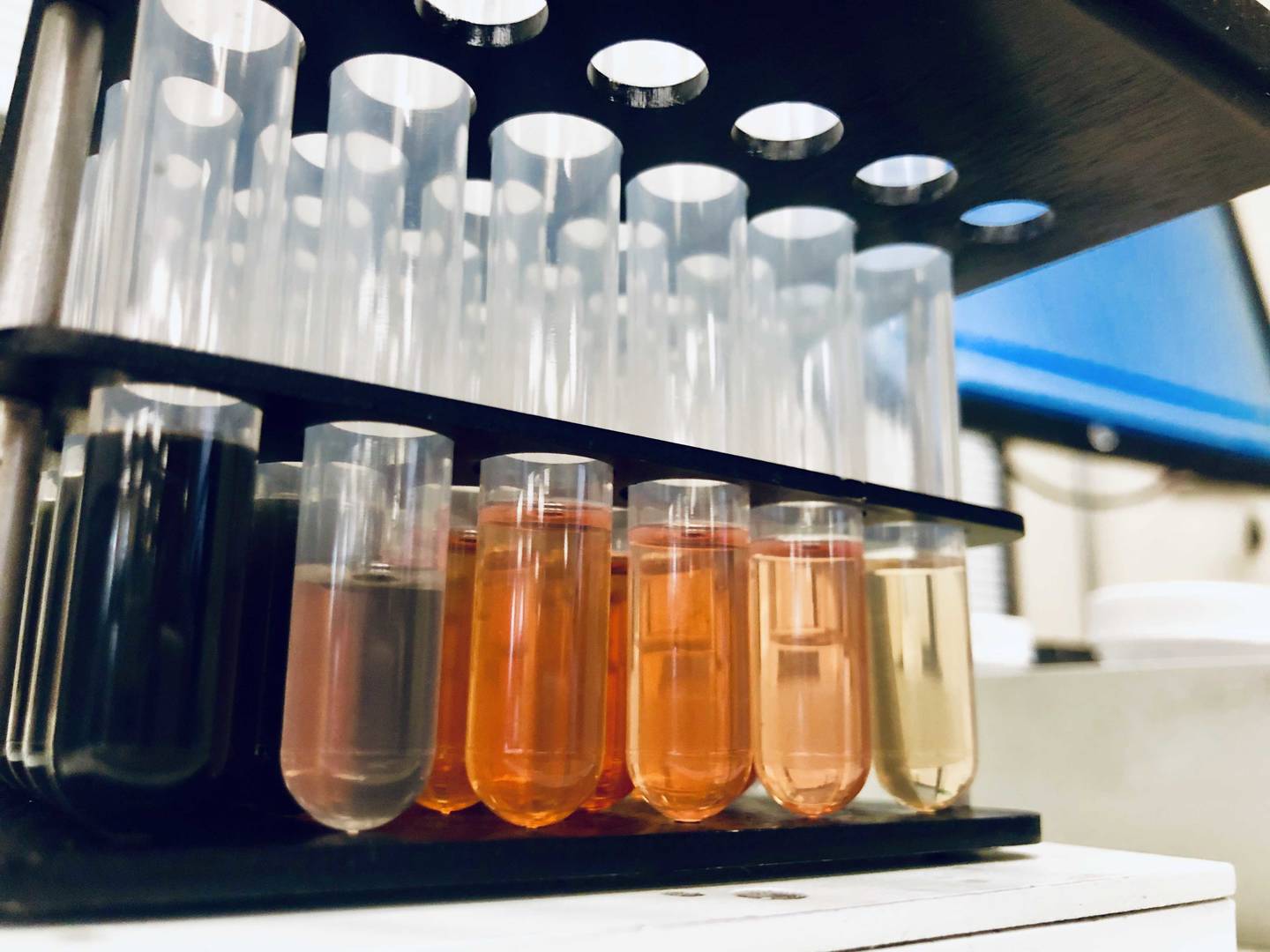

Choose from a Wide Range of Heavy Liquid Densities

HLS testing can separate samples at a single density, resulting in a pair of sink-float products or into a range of density intervals with a minimum density increment as small as 0.1. Static separations are performed on coarser-grained fractions (greater than 0.5 mm) and for size fractions less than 0.5 mm, separations are usually performed in a centrifuge. This method is effective down to particle sizes as fine as 45μm and, with modifications, reasonable separation can be achieved on fractions as fine as 10μm.

The resulting size fractions are then weighed and assayed. Calculated weight and element distribution data can then be used to indicate optimum density cut points or product weight splits to achieve the desired results in terms of grade and/or recovery. Once produced, the density fractions can be submitted for analysis at our in-house analytical and mineralogical laboratories.

ALS are able to provide testwork data on samples across a range of commodities including:

- Iron Ores

- Mineral Sands

- Base Metals

- Precious metals including Gold and PGMs

- Uranium

- Industrial Minerals

List of heavy liquids available for use together with SGs are tabulated below.

Vyhledat

Vyhledat

čeština

čeština

Login

Login