Technical Services 4 United Kingdom

Optimising Cooking Instructions

Consumer preferences and perceptions of air frying vs. traditional methods

Introduction

In the last years in UK there has been a significant shift in how consumers cook food, with a notable increase in the demand for air fryers. This surge in popularity is largely due to air fryers being a healthier alternative to traditional frying methods and more energy-efficient compared to conventional ovens. The rising energy prices for electricity and gas have driven consumers to seek more cost-effective cooking methods, and air fryers have become a preferred choice due to their quick cooking times and low operational costs. Additionally, air fryers offer versatility with various cooking methods such as baking, dehydrating, grilling, and air frying.

Extensive research has been conducted comparing air frying with other cooking methods, exploring topics such as nutrient retention, heat transfer, acrylamide formation, and overall product quality—the latter being the main focus of this article.

As Arafat (2014) reported, deep-fried products typically exhibit high heat transfer during cooking, which is crucial for achieving the desired organoleptic properties. However, consumer preferences have recently shifted toward healthier cooking options, including low-fat or fat-free alternatives.

The use of hot air instead of hot oil to cook food is a novel approach, alongside others, that have emerged as alternatives to deep-frying, as highlighted by Téllez-Morales et al. (2024). This method employs dry heat rather than a hot liquid, resulting in shorter frying times and an outer texture that mimics the characteristics of deep-frying, as noted by Coria-Hernández et al. (2023). Basuny (2016) observed that potato chips cooked in an air fryer achieved sensory characteristics comparable to those produced by traditional frying methods, while exhibiting lower oil retention and reduced acrylamide formation.

Increasingly, food products in the market now include air frying as part of their cooking instructions on the packaging. This creates a need for generating instructions that ensure the cooked product is both safe to eat and comparable in quality to those prepared using classic cooking methods.

According to BRCGS Food Safety Issue 9, ready-to-be-cooked food is defined as food that requires cooking or other processing to effectively eliminate or reduce microorganisms of concern to an acceptable level. Cooking is defined as a thermal process designed to achieve a 6-log reduction in Listeria monocytogenes, equivalent to 70°C for 2 minutes. Cooking instructions then, are primarily intended to ensure food safety, but sometimes the minimum cooking time may not meet the desired quality standards. Consequently, cooking times are often extended to balance safety and quality considerations.

The quality of a product significantly impacts brand reputation and consumer trust. Conducting validation replicates of back-of-pack cooking instructions demonstrates manufacturers' control steps for raw products that have not previously undergone sufficient microbial control. It is essential to consider both food safety requirements and organoleptic quality when generating cooking instructions.

Objective

This brief study aimed to combine a comparative sensory experiment between air frying and traditional cooking methods while demonstrating that the quality of the cooked product is a critical factor to consider when developing new cooking instructions, alongside the minimum food safety requirements.

To achieve this objective, cooking instructions for oven baking, deep-fat frying, and air frying of breaded chicken fillets were designed to meet only the minimum food safety standards. A panel of 36 average consumers was then employed to evaluate their preferences for the cooked samples.

Method

Cooking instructions were generated for three methods— air frying, fan-assisted electric oven baking, and deep-fat frying—for a single product. These instructions were designed to meet the minimum food safety requirements, the organoleptic quality of the cooked product was not considered during this process.

For the oven method, temperature probes were inserted into the chicken fillets at the start of cooking. The internal temperature was monitored for at least 7 minutes, after which the fillets were turned, and monitoring continued. It was determined that 14 minutes of cooking at 180°C was sufficient to meet safety requirements, validated by performing the process in triplicate.

For the air fryer method, the same approach was used. Cooking instructions were developed and validated specifically for ALS’ 3.8L 1500W air fryer. It was determined that 14 minutes at 180°C, with the product turned halfway through, ensured the minimum safety standards.

For the deep-fat fryer method, high frying temperatures made it impractical to monitor the internal temperature during cooking. Instead, probes were used to measure the temperature immediately after cooking. Initial testing based on existing guidelines suggested 2 minutes of frying, but this was insufficient to reach 70°C. After increasing the time by 30-second intervals, it was found that 3 minutes and 30 seconds at 180°C were required to meet safety requirements.

Cooking Instructions:

- Oven Cooking: Preheat oven to 180°C (fan). Remove all packaging. Place chicken mini fillets on a wire rack over a baking tray and cook in the centre of the oven for 14 minutes, turning halfway through.

- Air Fryer Cooking: Preheat air fryer to 180°C for 3 minutes. Remove all packaging. Place chicken mini fillets on a wire rack and cook for 14 minutes, turning halfway through.

- Deep-Fat Frying: Preheat fryer to 180°C. Place six fillets in the fryer basket and cook for 3 minutes and 30 seconds.

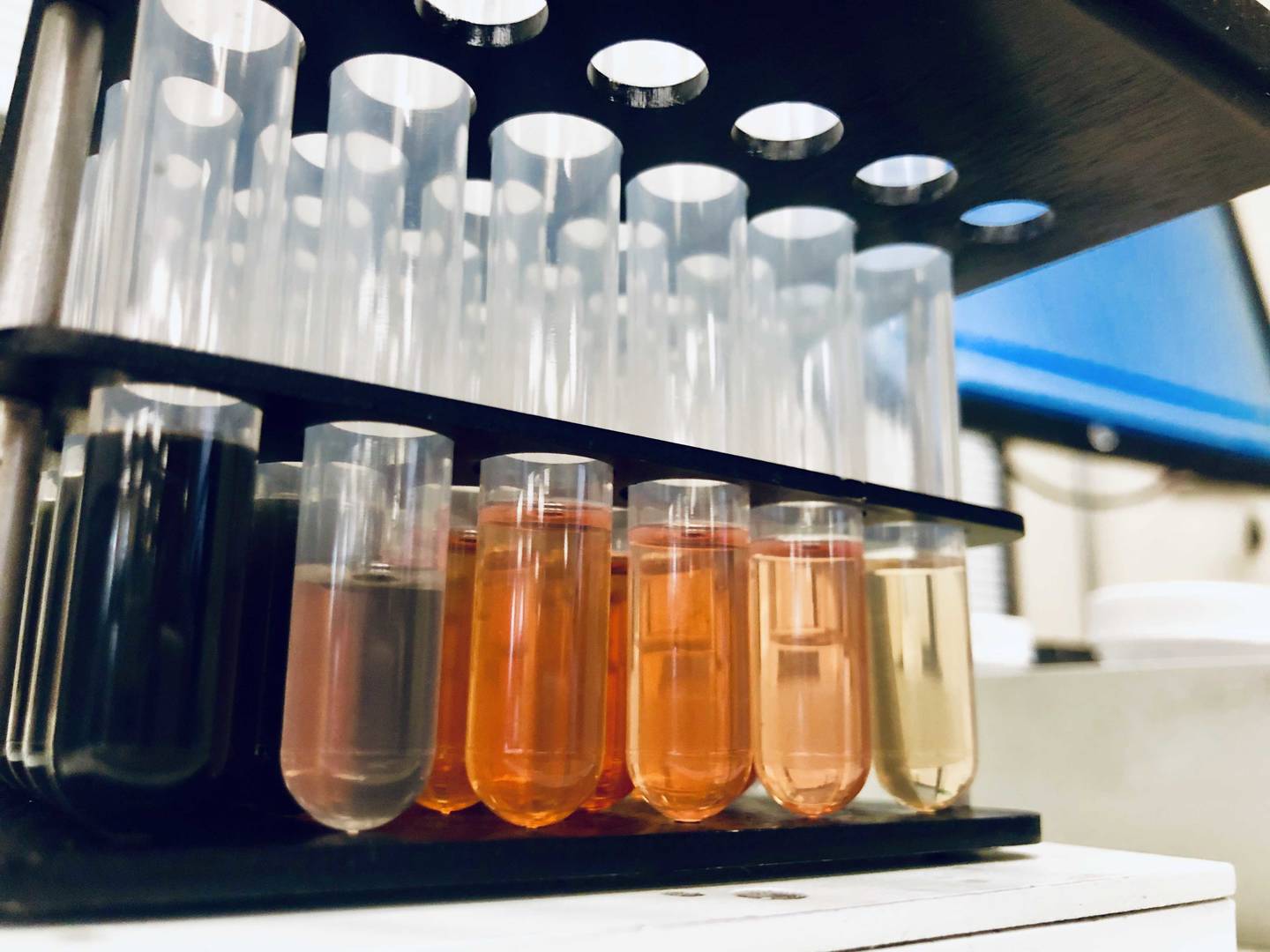

The cooked products from each method are shown in Figure 1 (a, b, and c).

Consumer Testing

Thirty-six participants evaluated the chicken prepared using each method based on organoleptic qualities, including taste, aroma, texture, and mouthfeel. Each participant received three pieces of chicken—one from each cooking method—without knowing which was which and ranked them based on preference.

For each attribute, panellists ranked the samples from first to third place. Given the nature of the product, particular emphasis was placed on greasiness and the texture of the coating. At the end of the questionnaire, participants were also asked to indicate which of the three cooking methods they would prefer to use when preparing the same product at home.

Figure 1. a) Oven, b) Air Fryer, c) Deep Fat Fryer

Results

Attribute Scores – Colour, Smell, Flavour

Consumers’ preferences for colour, smell and flavour are summarised in Figure 2, with percentages indicating the proportion of participants ranking each method 1st (gold), 2nd (silver), and 3rd (bronze) for each attribute.

The deep-fat fryer result showed the highest percentage for 1st place, and therefore was the most preferred cooking method based on colour. With air fryer the second favourite and oven the least preferred. Therefore, deep-fat frying created the more visually appealing sample.

Interestingly, the oven method was the most preferred for smell, ranking 1st and 2nd (39% each), while the deep-fat fryer had the highest 3rd place ranking , or ‘least favoured’ (44%), likely due to the oil used in frying. While vegetable oil was used during testing, consumer preferences might have differed with an alternative oil.

On the contrary, deep-fat frying was the most favoured for flavour, whereas the oven-cooked fillets were the least preferred (50% ranked them 3rd). Background research suggests that frying enhances crispiness and crunchy mouthfeel, which may explain its higher preference for flavour.

Attribute Scores – Texture & Greasiness

Figure 3 presents consumer rankings for three key texture-related attributes: texture of coating, texture of meat, and greasiness across air frying, oven baking, and deep-fat frying.

As expected, deep-fat frying was the most preferred method for the texture of the coating (53% of participants ranked it 1st). The high heat transfer and quick cooking times cause the outer coating to cook and change colour faster than with oven methods. This rapid heat transfer also helps the meat retain more moisture, creating the most desirable contrast between a crispy outer layer and a tender inner. Oven-cooked samples were ranked 3rd by the majority (61%), as the coating remained soft and soggy in comparison.

Deep-fat frying was also the most favoured method for the texture of the meat, with the air fryer coming in a close second for both texture-related attributes. The oven method again ranked 3rd.

Finally, the oven method was perceived as the least greasy (42% ranked it 1st), while deep-fat frying was the least preferred for this attribute (44% ranked it 3rd), confirming its association with a higher oil content.

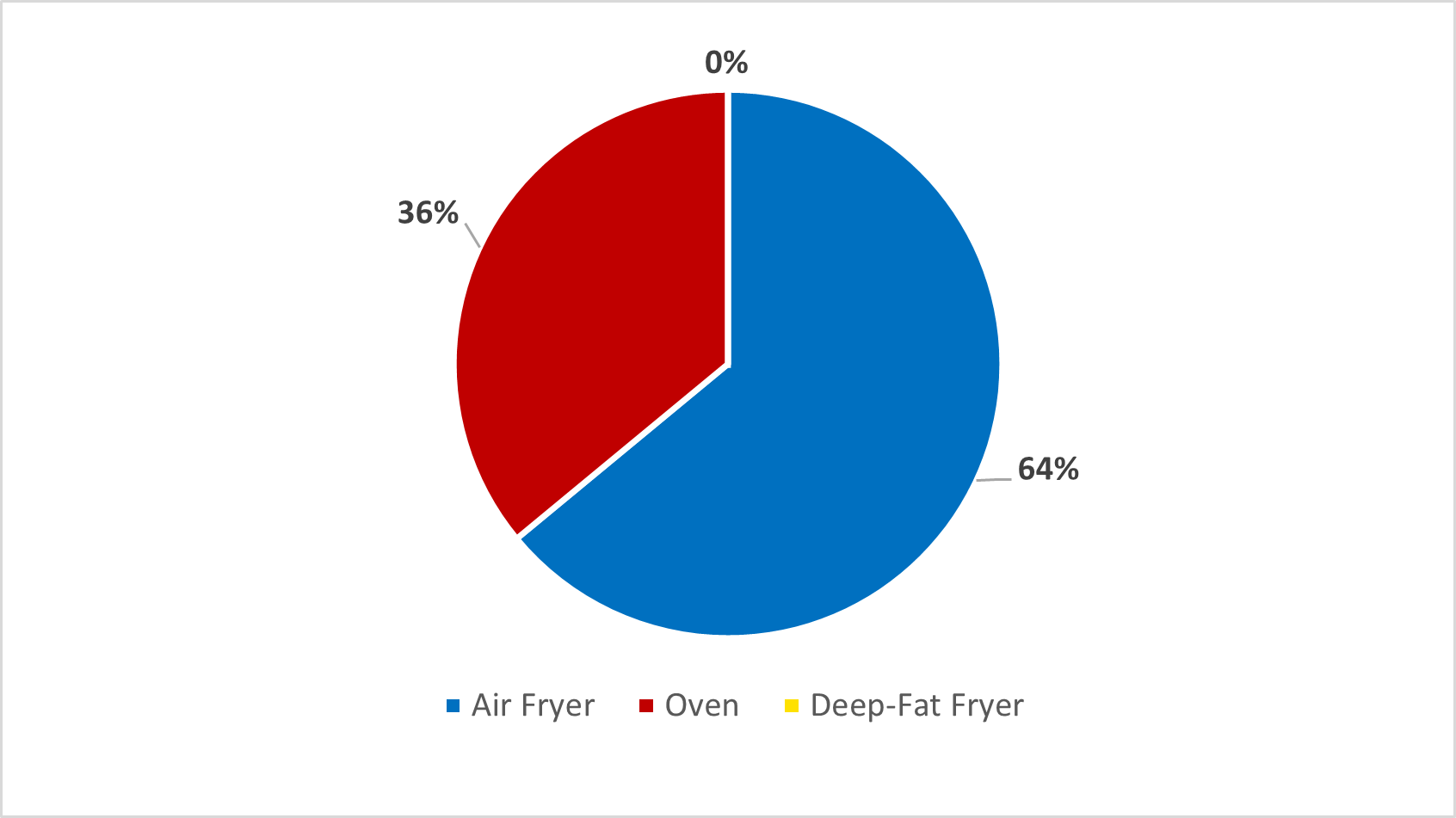

Cooking preferences

As the final question, consumers were asked to indicate which cooking method they would prefer using at home among the three proposed options. As shown in Figure 4, 64% of participants would choose air frying as their preferred method for cooking breaded chicken fillets. The remaining 36% would opt for a standard oven, and none of the participants would choose to use a deep-fat fryer to cook this product at home.

Some final key considerations can be drawn from the results of this study:

- The fact that the cooking instructions were developed without considering the final organoleptic quality of the cooked product may have influenced the consumer testing results. Specifically, for oven cooking, slightly longer cooking times could have improved rankings, particularly for texture attributes.

- When developing cooking instructions, the quality of the final product should not be overlooked. All labelled instructions should aim to achieve the best organoleptic results alongside ensuring food safety.

- Overall, air frying showed consistent consumer appreciation, highlighting its versatility and positive reception.

Conclusion

In conclusion, the results of this study emphasize the growing shift towards air frying as a preferred cooking method for breaded chicken fillets, with 64% of participants selecting it as their preferred option for home use. While traditional methods such as deep-fat frying and oven cooking continue to hold a place in households, air frying demonstrates significant consumer appreciation due to its versatility, reduced odour, and overall positive organoleptic outcomes. The preference for air frying, despite deep-fat frying being favoured in certain texture attributes, highlights the evolving consumer preferences for more convenient, less greasy cooking options. As air fryer ownership increases, this method is likely to become the dominant choice for preparing crispy, tender dishes. For future product development and cooking instruction design, it is crucial to balance the organoleptic quality with ease of use, ensuring that the best cooking outcomes are achieved across various methods.

References

- Shaker, M. Arafat. Air Frying a New Technique for Produce of Healthy Fried Potato Strips. Journal of Food and Nutrition Sciences. Vol. 2, No 4, 2014, pp.200-206. doi: 10.11648/j.jfns.20140204.26

- Téllez-Morales JA, Rodríguez-Miranda J, Aguilar-Garay R. Review of the influence of hot air frying on food quality. Measurement Food. 2024;14:100153. doi:10.1016/j.meafoo.2024.100153

- Coria‐Hernández J, Arjona‐Román JL, Meléndez‐Pérez R. Comparative study of conventional frying and air frying on the quality of potatoes (Solanum tuberosum L.). Food Science & Nutrition. 2023;11(10):6676-6685. doi:10.1002/fsn3.3617

- Basuny, A.M, Oatibi H.H. Effect of Novel Technology (Air and Vacuum Frying) on Sensory Evaluation and Acrylamide Generation in Fried Potato Chips. Banat’s Journal of Biotechnology. 2016; doi: 10.7904/2068–4738–VII(14)–101