Technical Services Article 3 United Kingdom

Consumer Preference of cola drink based on packaging type - Glass / Plastic / Can

Background

Choosing the packaging material for food and beverages can be product dependant. A paper/cardboard packaging may not be suitable for a greasy/liquid product that may leak easily, whereas a plastic container may be more ideal. Other aspects to consider are product safety, shelf life, sustainability, and product/brand integrity. All these attributes can influence consumer preference and buyer choice. For example, if a product is tainted, has off-colours/odours/tastes/textures, then purchase intent may fall, and these attributes can be affected by packaging materials. Enjoyment and positive sensory stimulation of a product can affect the repeat purchase of a packaged food product (Kilcast, 1996).

Properties such as reusability, recyclability are important factors for many consumers nowadays. An incorrect choice of packaging material can negatively affect the quality of the product or the consumer perception. For example, a cake in packaging that can be recycled may be preferred over one where the packaging cannot. Therefore, research into optimum packaging for food and drink is a fundamental step in product development.

Food or beverages’ original packaging may not be the same as what we see on our shelves today. Previously packaging may have been dependant on material costs or even availability. Hence, what companies use today may not be used in the future.

Looking Back

The way food is preserved or transported has changed a lot throughout history, reflecting the needs and characteristics of society.

We know that the first containers were created more than 10,000 years ago and throughout our history they have evolved according to our needs, and even as part of the evolution of the expression of art of different civilizations, using different materials, decorations or shapes.

In prehistoric times, natural packaging such as animal skins, leaves or shells were used to protect and cover food. Later, with the development of craftsmanship, these evolved into wooden or clay containers like amphora (Syria, Egypt, or Mesopotamia, and later Greece and the Roman Empire who perfected it, making it an iconic element of their culture.) some of which have reached present days providing us with information on ancient cultures. The Egyptians produced the first glass containers dating back to 1500 B.C. which later (around 250 B.C.) the Babylonians perfected with blowing techniques.

The creation of paper dates back to 105 A.D in Ancient China and in addition to documentary use, it began to be used as a container for fresh products, although it was not until many centuries later that it would reach the West.

It was not until 1810 that Peter Durand, a British merchant, designed and patented the first cylindrical metal container.

The use of cardboard as a material for preserving food dates back to the early twentieth century. The same century in which we saw the birth of a new material for packaging and preserving food or beverages, plastic, which is very easy to produce compared to other options.

Evolution has continued to advance to the present day thanks to new technologies, designing combinations of materials, quantity, affordability and lately, an increasing demand for products that are recyclable. It is important to recognise what we have used in the past, present and what we will in the future of food/beverage packaging materials.

Packaging Types

It is important to understand the material interaction between the package and the product; chemical migration, absorption and more. One of the greatest risks is from contact of foods with materials that may contain potential migrants (Baigrie, 2003, Kilcast, 1996, Reineccius, 2006).

Modern legislation guards against the spoilage of foods by packaging materials by regulating that food packaging materials do not transfer constituents to foods in sufficient quantities to endanger human health or cause deterioration of the sensory characteristics of foods (Huber et al., 2002, Soderhjelm and Eskelinen, 1985).

Reactions such as oxidation, hydrolysis, and vaporization can lead to the production of off‐odours and flavours and changes in texture and visual characteristics (Ayhan et al., 2001). These changes may be caused by the packaging materials themselves, by an interaction between the package and the food, and/or because of poor packaging selection (Huber et al., 2002).

Case Study

How often have we heard people state that they can taste the difference or have a ‘favourite’ packaging relating to the taste of cola beverage?

With the wealth of available information on different types of packaging, ALS wanted to investigate whether a consumer test would depict any sensory differences in a product that uses various packaging types. Cola is a typical carbonated drink that can be bought in any of the below materials. Plastic bottles with plastic cap, glass bottle with metal cap or aluminium can with a ring pull. There are many discussions and options over which cola individuals prefer based on packaging.

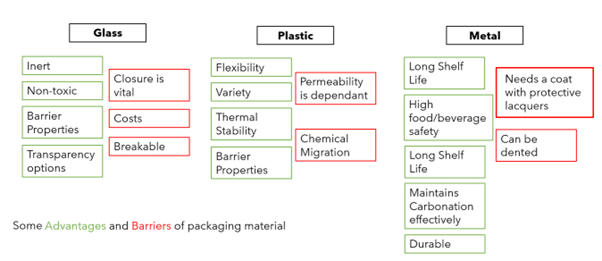

Diagram 1 - Several of the pros and cons for each packaging materials.

Methodology

A product with the exact same ingredients from the same brand was selected, the only difference was the packaging material.

A group of 24 untrained panellists were recruited. During a selection criteria stage, anyone that suffered from any allergies listed in the ingredients list, or who did not routinely consume this type of beverage were eliminated from the study.

Panellists were briefed on the study before taking part.

A controlled environment was created in accordance with “BS EN ISO 8589 2010 A1 2014 Design of test Rooms” using standardized lighting (standard correlated colour temperature (6500k) and between 755 and 1070 lux) in ALS’ sensory facility.

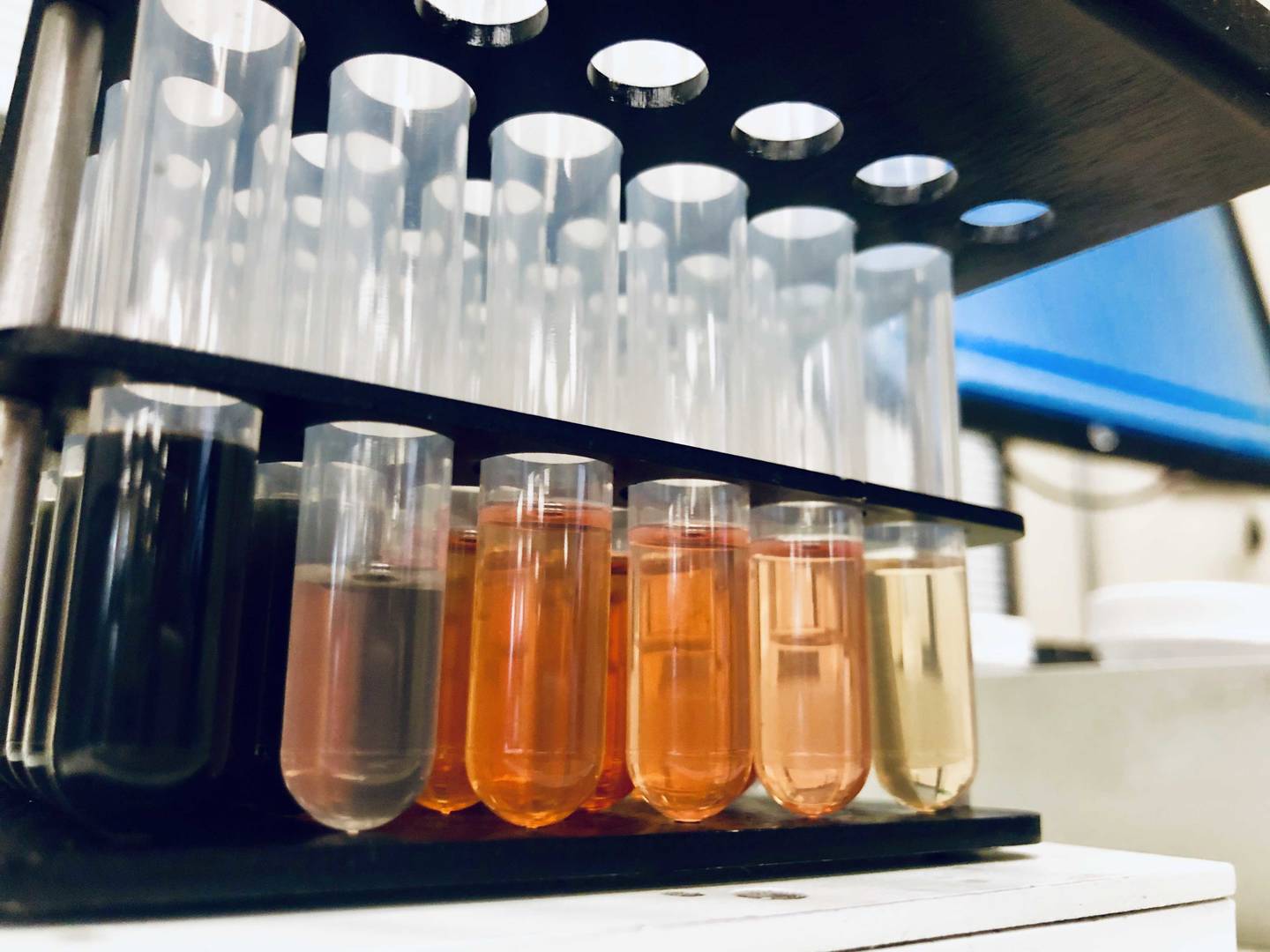

The samples were prepared according to “BS ISO 6668 2008: Preparation of Samples”. In this study the panellists were given a 100ml sample of each different product, these were labelled with randomised blinding codes. With each sample, a water cracker and cup of bottled water was given to cleanse the palate between tastings.

Panellists were then given a series of questions to answer about the products to investigate consumer opinions on the carbonation and strength of flavour. Just about right (JAR) scales were used to score the key attributes of the samples.

Once completed, panellists were taken to a meeting room to discuss their preferences and to be debriefed.

Results

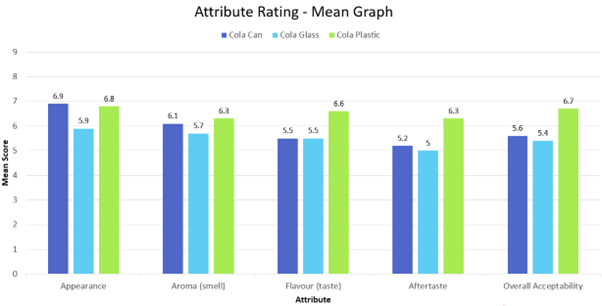

Graph 1 - Mean graph of the Sensory Attributes

Graph 1 shows the mean results of scores of the different sensory attributes the panellists assessed. The highest scoring for overall acceptability and flavour was the sample from plastic packaging.

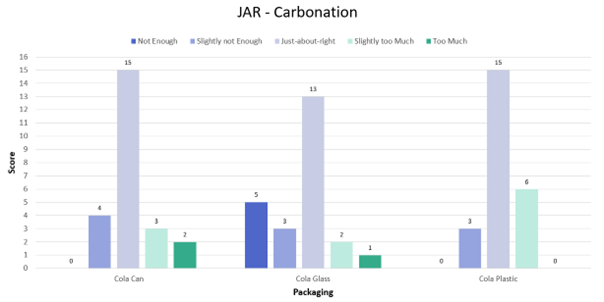

Graph 2 - Cross-tabulation of Carbonation

The JAR graph shows the results of the scoring for the carbonation of the cola drink. The higher score for value 1, ‘not enough’ carbonation, was from the glass packaging, the score value 3, ‘just–about-right’ amount of carbonation, was equal in can and plastic.

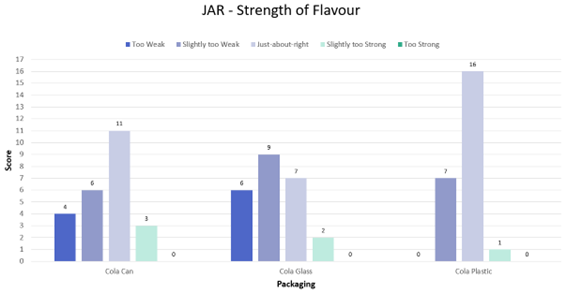

Graph 3 - Cross-tabulation of Strength of Flavour

The JAR graph shows the panellists’ scores on the strength of cola flavour between samples. The highest score for ‘just-about-right’ was for the plastic packaging. The sample in a can was found to have the weakest strength according to the panel.

Conclusion

Overall, the results from the study suggest that the cola from a glass bottle was deemed not carbonated enough compared to the other two samples. Furthermore, the cola from the plastic bottle and can, were equally scored for ‘just-about-right’ value. Due to the cola from plastic packaging scoring highest in flavour and overall acceptability, this suggests that consumers preferred this product over the samples from a can and glass bottle based on consumption.

Panellists were never exposed to the three types of packaging, and therefore this test only reveals results from a blind sensory study. To assess consumers’ preference on the experience of drinking the beverage from its original packaging material, further studies are required.

Please note that this study is based on the preferences of the consumer panel involved. Due to the nature of a consumer test, the results are based on subjective answers depending on individual preferences.

Contact

For more information or support on this topic, or if you’d like details on the sensory analysis services offered by ALS Laboratories, please contact our Technical Services Team at Fullsense.UK@ALSGlobal.com or Consultancy.uk@ALSGlobal.com

References

- Abramowicz, DA et al. (2013). Innovations and trends in metal packaging for food, beverages and other fast- moving consumer goods. In: Farmer, N (Ed.) Trends in packaging of food, beverages and other fast- moving consumer goods (FMCG) Markets, materials and technologies. Woodhead Publishing Ltd.

- Chen, M, Wang, Y, Wang, L, Yin, S (2014). Effects of Temperature and Humidity on the Barrier Properties of Biaxially-oriented Polypropylene and Polyvinyl Alcohol Films. Journal of Applied Packaging Research 6 (1) 40-46.

- Fereydoon, M, Ebnesajjad, S (2013). Development of High-Barrier Film for Food Packaging. In: Ebnesajjad, S (Ed.) Plastic films in food packaging, Materials, Technology, and Applications. Elsevier Inc.

- Galić, K, Ciković, N (2003). The effect of liquid absorption on gas barrier properties of triplex film coated with silicon oxide. Food Technology and Biotechnology 41, 247-251.

- Girling, PJ (2003). Packaging of food in glass containers. In: Coles, R, McDowell, D, Kirwan, MJ (Eds.) Food Packaging Technology, Blackwell Publishing Ltd.

- Hirvikorpi, T, Vähä-Nissi, M, Nikkola, J, Harlin, A, Karppinen, M (2011). Thin Al2O3 barrier coatings onto temperature-sensitive packaging materials by atomic layer deposition. Surface & Coatings Technology 205, 5088–5092.

- Howells, DG et al. (2008). Mechanical properties of SiOx gas barrier coatings on polyester films. Surface & Coatings Technology 202: 3529–3537.

- Jellesen, MS, Rasmussen, AA, Hilbert, LR (2006). A review of metal release in the food industry, Materials and Corrosion 57 (5) 387-393.

- Kim, S-R, Choudhury, MH, Kim, W-H, Kim, G-H (2010). Effects of argon and oxygen flow rate on water vapor barrier properties of silicon oxide coatings deposited on polyethylene terephthalate by plasma enhanced chemical vapor deposition. Thin Solid Films 518, 1929-1934.

- Kirwan, MJ, Plant, S, Strawbridge, JW (2011). Plastics in Food Packaging. In: Coles, R, Kirwan, M (Eds.) Food and Beverage Packaging Technology, 2nd ed., Blackwell Publishing Ltd.

Paul, DR, Robeson, LM (2008). Polymer nanotechnology: Nanocomposites. Polymer 49, 3187–3204. - Restuccia, D et al. (2010). New EU regulation aspects and global market of active and intelligent packaging for food industry applications. Food Control 21,1425–1435.

- Roberts, AP et al. (2002). Gas permeation in silicon-oxide/polymer (SiOx/PET) barrier films: role of the oxide lattice, nano-defects and macro-defects. Journal of Membrane Science 208, 75–88.

- Robertson, GL (2013). Food Packaging: Principles and Practice (3rd edition), CRC Press. Taylor & Francis Group.

- Sorrentino, A, Gorrasi, G, Vittoria, V (2007). Potential perspectives of bio-nanocomposites for food packaging applications. Trends in Food Science and Technology. 18, 84–95.

- Stamm, H, Gibson, N, Anklam, E (2012). Detection of nanomaterials in food and consumer products: bridging the gap from legislation to enforcement. Food Additives and Contaminants 29 (8) 1175–1182.

- Susan E. Duncan, Janet B. Webster (2009). Chapter 2 Sensory Impacts of Food–Packaging Interactions, Advances in Food and Nutrition Research, Volume 56, Pages 17-64,

- Yam, KL, Takhistov, PT, Miltz, J (2005). Intelligent Packaging: Concepts and Applications. Journal of Food Science 70 (1) R1-R10.