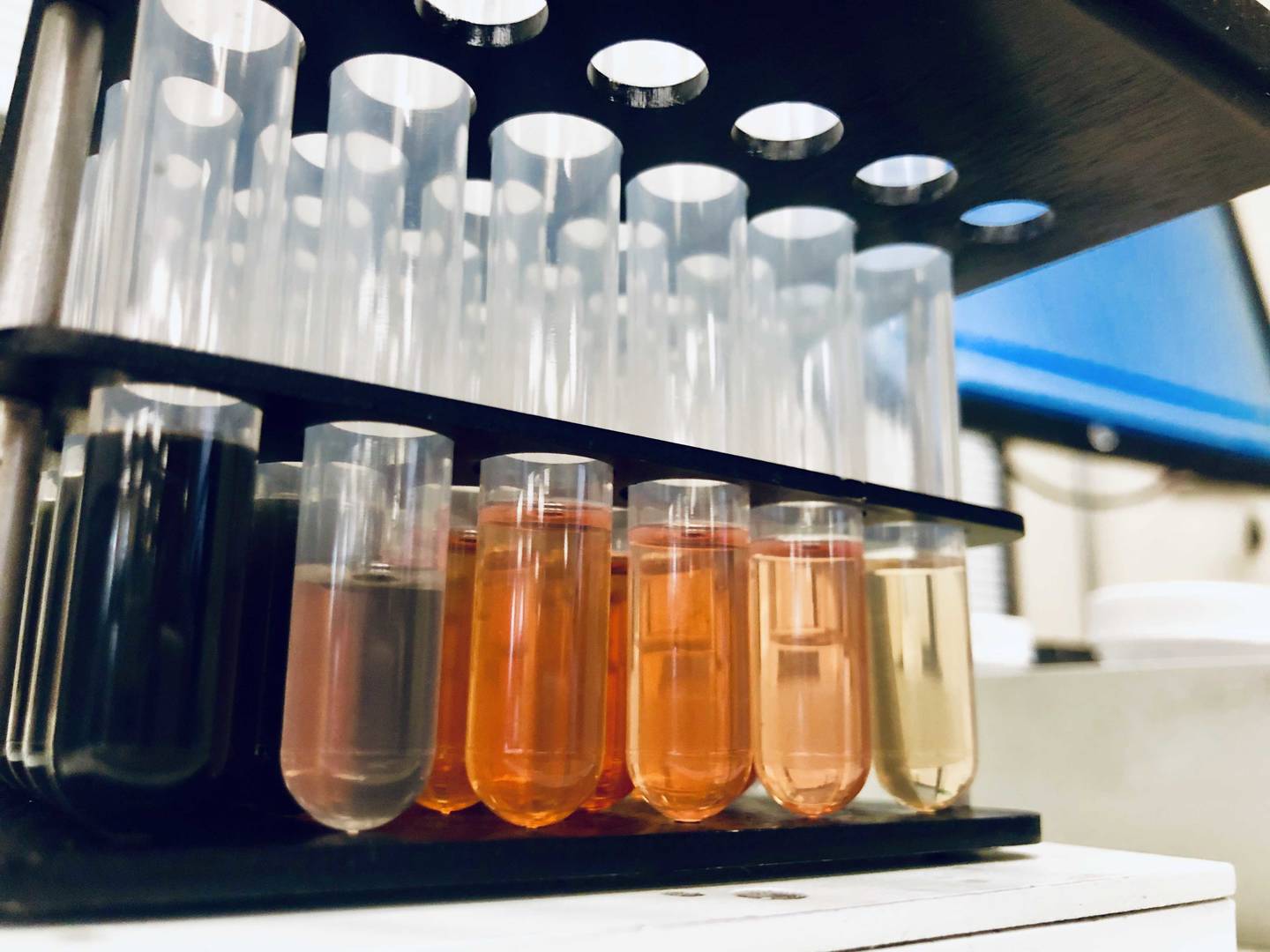

Piloting Testwork Services

Every pilot plant is different. For this reason, ALS chooses a modular (skid-mounted) approach to pilot plant set-up to effectively allow unlimited options. Each of the skids, plant modules, or proprietary equipment items must be connected via pipes and pumps, and at times decoupled by surge tanks and/or stop points requiring full dewatering and drying. Set-up needs to be as ergonomic as possible to allow for safety, sampling, and resources. If we don’t have the exact equipment in our inventory, then usually there is an engineering/fabrication solution, purchase/hiring of new equipment, or leveraging of alliances with vendors (e.g. Eriez, Outotec-Metso, Tomra, Köeppern). We always work something out.

Broad pilot plant set-ups fall into the following categories (click on the links for more detail):

One critical element of testing common to all pilot plant is sampling and monitoring, together with all of the infrastructure to process the samples and data collection. ALS has the complete capability to facilitate all requirement of sampling, from drying, preparation, sizing, analysis, and dispatch to third parties.

ALS always keeps sample representivity in mind when designing the sample process and taking the samples from the plant/process. Representative samples lead to statistical veracity and ultimately to a meaningful mass balance properly capturing plant performance at the target product specification. Wherever possible, ALS uses the principal of cutting full stream for a significant time (for flowrate streams) or using proven sampling techniques (i.e. Cone and Quartering, Riffle Splitting, and/or rotary sample dividers) for bulk solids parcels).

Typical pilot sampling requirements are as follows:

- Head samples

- Sizing samples

- Control grab samples

- Shift Composite

- Survey samples

- Reagent additions

- Probe monitoring

- Engineering/vendor samples

Finally, it comes down to mass reconciliation. We understand the importance of your samples, and from hard lessons that were learned in the early days. ALS takes extraordinary care in capturing and measuring every stream. Spillages and losses (e.g. to dust and moisture) are unavoidable, but strict sample collection and measuring control, ALS routinely has mass reconciliation at 99.5% (i.e. 0.5% unaccounted loss).

Vyhledat

Vyhledat

čeština

čeština

Login

Login