EnviroMail 31 USA

Using Incremental Sampling Methodology (ISM) to Optimize Sample Integrity

Incremental Sampling Methodology (ISM) offers a systematic approach to obtaining and analyzing representative samples.

Overview of Incremental Sampling Methodology (ISM)

Incremental sampling methodology (ISM) is a group of procedures starting with field sampling and extending to sample handling in the laboratory. Project planning is an extensive process that amongst other elements will include definition of sampling area referred to the decision unit (DU), and the number of samples collected from the grid within the decision unit. The samples from the decision unit are combined to form a single bulk sample. Sample handling in the laboratory continues this homogenization process. The purpose of the ISM protocols is to ensure the final sample aliquot used for sample preparation and subsequent analysis is representative of the decision unit.

ISM Procedures for Field Sampling and Laboratory Subsampling

The use of ISM procedures for field sampling and laboratory subsampling is recommended by EPA method 8330B (2006) for explosive compounds. The ISM subsampling procedures employed in the lab were developed to ensure the sample aliquot used for sample preparation and subsequent analyses are representative of the decision unit from which the bulk sample was collected.

Implementation of ISM Procedures

Procedures detailed in Method 8330B were initially implemented in the ALS Middletown laboratory to support ISM projects specifically for explosives and later expanded the in scope for to include metals analyses. Steps for ISM techniques in the laboratory add significant time for sample processing prior to the extraction and the analytical finish.

Laboratory Steps in ISM

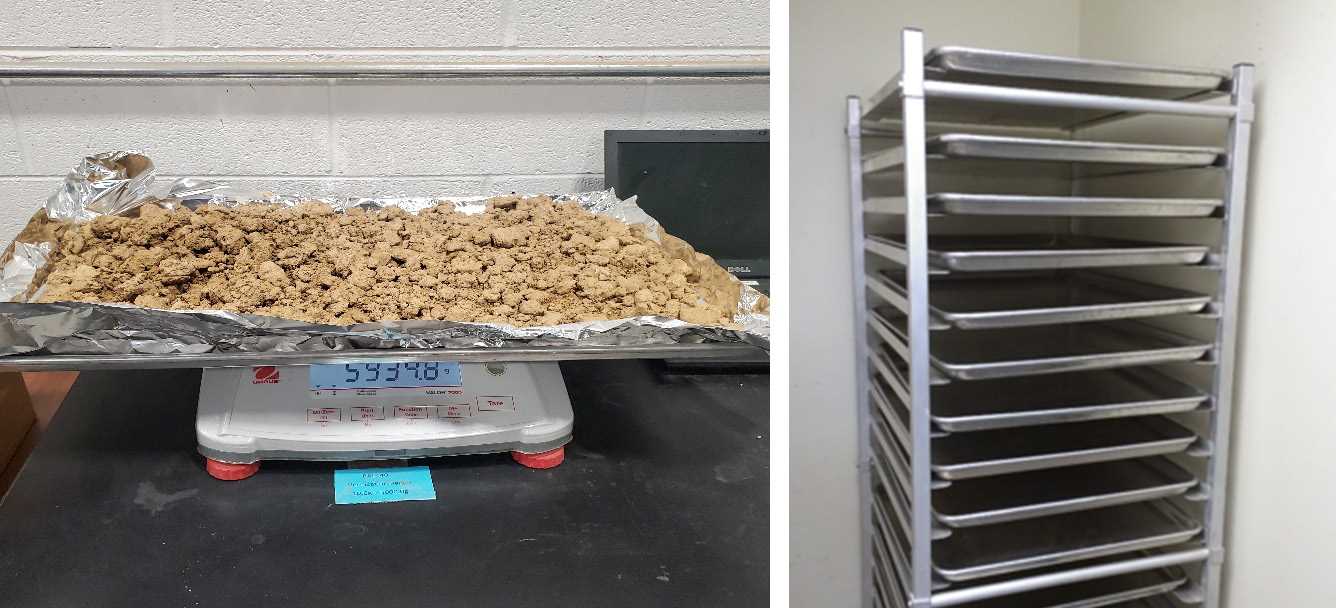

Drying

The entire contents of the bulk sample is spread out evenly on a drying pan. Large chunks are broken up to expedite sample drying. The “as received” soil weight is determined for later assessment of the drying status. Samples are air-dried at room temperature to a constant weight. Each sample is re-weighed following a twenty-four hour minimum drying time. Subsequent sample weights are taken at increments no less than two hours until constant weight is achieved. Sample composition, soil type, and moisture content have a direct impact on the drying time.

Picture 1: Drying sample and drying rack

Sieving

Particle size reduction is an essential component of the ISM to create more consistent particle sizes. The sample is passed through a 10-mesh sieve to achieve particle sizes of 2 mm or less. This will reduce stratification within the bulk sample and facilitate homogeneity and a representative subsample. It is usually necessary to use a mortar and pestle to break up sample aggregates to ensure all soil from the sample passes through the sieve. Rocks and other materials greater than 2mm that do not pass through the sieve are collected, weighed, and saved in the event the client requests further processing.

Metals Subsampling

Further milling for metals analysis may not be appropriate based on the targeted metals. Knowledge of the puck-mill composition is necessary to make this determination. If milling is omitted for metals analysis, a sub-sample incrementally collected from the dried and sieved bulk sample. Incremental sampling is achieved by creating a six by five grid in the tray and collecting a 0.3 to 0.35g sample amount from each of the thirty sections in the grid to yield approximately 10g of samples.

Milling

A puck mill consisting of the Mill, a 2000 cubic centimeter steel bowl, steel lid, and a steel puck is employed for this final step. Milling will further reduce sample particle sizes and the sample has the consistency of a free-flowing powder. This will further enhance the ability to collect a subsample representative of the initial bulk sample received by the lab.

Example of effectiveness of puck mill to reduce particle sizes is illustrated in Picture 4. The pile of material on the left is Ottawa sand with no additional processing. The pile of material on the right is Ottawa sand that has been milled.

Subsampling

A final sub-sample is incrementally collected using the same procedure as described for metals subsampling above. To demonstrate sample homogeneity, a minimum of one sample per extraction batch will be sub-sampled and analyzed in triplicate. This is a recommendation in EPA Method 8330B and a DoD ELAB requirement detailed in the Quality Systems Manual.

Extraction and Analysis

Subsamples and associated quality control samples are submitted for extraction. The extraction procedures for EPA 8330B includes the addition of surrogates to all samples, spike solutions to sample aliquots selected for matrix spiking, and the addition of the extraction solvent. Following an eighteen-hour extraction procedure, the samples are filtered and are submitted for analysis by HPLC with UV detection.

Expansion of ISM Protocols

Incremental Sampling Methodology (ISM) protocols were initially employed for explosives and metals analysis at the ALS Middletown lab. Application of ISM protocols has been expanded to other analyses such as semi-volatiles, volatiles, pesticides, and PCBs. Due to varying analyte stabilities and volatility, handling will vary. More specifically, subsamples for the different analyses will be formed at different points of the process detailed above. The Incremental Sampling Methodology Guidance documents (ISM-1 2012 and ISM-2 2020) issued by the Interstate Technology Regulatory Council (ITCR) are recognized as the industry standard for this sampling protocol. These documents provide recommendations and best practices for project planning. Finally, communication between the laboratory and the client is critical to ensure ISM procedures employed by the lab align with the project quality objectives.

Considerations and Costs

While the ISM procedure benefits the user of the data in that a representative sample can be used to determine contamination probabilities over larger ranges (without added costs related to individual test points), there are important considerations when using this technique. It requires planning and coordination in advance and at each step of the process. The ISM sample preparation can take days to complete at the laboratory. Drying time alone can take multiple days. The equipment used for this process is specialized and requires thorough cleaning between each sample, one at a time. ISM prep itself is costly for those reasons. Overall though, benefits of the process outweigh the cost of ISM prep to the client when organized and performed well.

To ensure the highest standard of sample integrity and data reliability in your environmental assessments, consider adopting Incremental Sampling Methodology (ISM) in your next project.

Contact ALS today to learn more about how ISM can optimize your sampling strategy and enhance the accuracy of your results.