EnviroMail 57 Canada

Testing for PBDEs & DecaBDE Flame Retardants to Assess Environmental Quality Guidelines

Polybrominated Diphenyl Ethers (PBDEs or BDEs) are a class of brominated flame retardant compounds, now largely banned globally and listed as persistent and bioaccumulative toxicants under the Stockholm Convention.

Figure 1. PBDEs were used extensively as flame retardants in commercial plastics, electronics, & textiles

Despite phaseout from common use many years ago, PBDEs remain ubiquitous global pollutants, and significant levels continue to be released to the environment from disposal or recycling of commercial products, from municipal sanitary and storm sewer effluents, and from landfill leachates. Canadian Federal Environmental Quality Guidelines for PBDEs in waters, sediments, and tissue/biota are very low, requiring analysis by specialty techniques such as Gas Chromatography with High Resolution Mass Spectrometry (GC-HRMS). For ultra-trace ambient water quality monitoring of pristine marine and freshwater environments, ALS can provide testing using semi-permeable membrane devices (SPMDs).

PBDE Background and Usage

Environmental and health concerns from PBDEs are due to potential cancer risks and to their classification as endocrine disruptors (they can disrupt central nervous system development and reproductive systems).

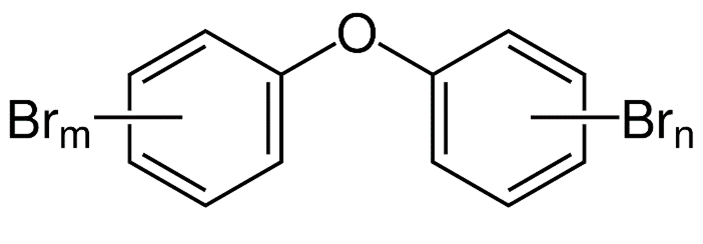

Although there are 209 possible congeners, ranging from mono to decabromodiphenyl ether, eight BDE congeners dominate in commercial products and in environmental presence, and are the primary congeners of concern (as per US EPA Method 1614A - listed in Table 1). The general chemical formula for PBDE is C12H(10−x)BrxO, as shown in Figure 2.

Table 1. BDE Congeners of Primary Concern (EPA 1614A)

| Dominant BDE Congeners | Full Parameter Name |

| BDE-28 | 2,4,4'-Tribromodiphenyl ether |

| BDE-47 | 2,2',4,4'-Tetrabromodiphenyl ether |

| BDE-99 | 2,2',4,4',5-Pentabromodiphenyl ether |

| BDE-100 | 2,2',4,4',6-Pentabromodiphenyl ether |

| BDE-153 | 2,2',4,4',5,5'-Hexabromodiphenyl ether |

| BDE-154 | 2,2’,4,4’,5,6’-Hexabromodiphenyl ether |

| BDE-183 | 2,2',3,4,4',5',6-Heptabromodiphenyl ether |

| BDE-209 | Decabromodiphenyl ether |

Heavily brominated substances are effective flame retardants because thermal energy causes the relatively weak carbon-bromine bond to release bromine radicals, which reduce the dispersion and rate of combustion of fire.

Large quantities of three types of commercial PBDE mixtures - known as PentaBDE, OctaBDE, and DecaBDE - were synthesized as flame retardants under various trade names for commercial products such as electronic equipment, furniture, and textiles, beginning in the 1970s. In the 1990s, over 50,000 tons of PBDEs were produced annually with Great Lakes Chemical Corp. being the primary producer in North America.

The PentaBDE commercial mixture contains predominantly pentabromo BDE isomers, with lesser amounts of tetrabromides and hexabromides, and traces of tribromides. Commercial OctaBDE is a mixture of hexa, hepta, octa, nona, and decabromides. Commercial DecaBDE is composed largely of the single decaBDE congener, with lesser amounts of nonaBDE isomers.

Table 2. BDE Homologue Group Details

| BDE Homologue Groups | Molecular Formula | Molecular Wt. (Da) | Bromine Wt% | Possible Congeners | Commercial Mixtures |

| Dibromodiphenyl ether | C12OH8Br2 | 328 | 48.7 | 12 | n/a |

| Tribromodiphenyl ether | C12OH7Br3 | 407 | 58.9 | 24 | PentaBDE |

| Tetrabromodiphenyl ether | C12OH6Br4 | 486 | 65.8 | 42 | |

| Pentabromodiphenyl ether | C12OH5Br5 | 565 | 70.7 | 46 | |

| Hexabromodiphenyl ether | C12OH4Br6 | 644 | 74.4 | 42 | |

| Heptabromodiphenyl ether | C12OH3Br7 | 723 | 77.4 | 24 | OctaBDE* |

| Octabromodiphenyl ether | C12OH2Br8 | 801 | 79.8 | 12 | |

| Nonabromodiphenyl ether | C12OHBr9 | 880 | 81.7 | 3 | |

| Decabromodiphenyl ether | C12OBr10 | 959 | 83.3 | 1 | DecaBDE* |

*Commercial OctaBDE may contain hexa & deca isomers. Commercial DecaBDE may contain nona isomers.

By 2008, production and use of commercial PentaBDE and OctaBDE had been banned in most countries, with DecaBDE still in use in some regions, but declining. Production of commercial OctaBDE and PentaBDE in the United States ceased at the end of 2004 after voluntary phase-out by the only US manufacturer (Great Lakes). In 2009, the two US producers and the main US importer of DecaBDE committed to phase out its use by the end of 2013. Most uses of DecaBDE in the US were banned by 2021, but it remains in limited use for some critical applications while alternatives are sought and approved.

Environmental and exposure impacts continue to occur from PBDEs due to commercial products still in use or from recycling and disposal (e.g. electronics, electric cables, furniture, polyurethane foam, carpets, and automotive/aerospace vehicles). Human exposure to PBDEs occurs largely from household dust, consumer products, and food sources.

PBDE Guidelines and Restrictions

Canadian Federal Environmental Quality Guidelines for PBDEs in waters, tissues, and sediments were established in 2013 by Environment Canada, as listed in Table 3. Most of the Canadian Federal PDBE guidelines were adopted in 2018 by Alberta in their Environmental Quality Guidelines for Alberta Surface Waters.

Tetra, penta, hexa, hepta, octa, nona, and decaBDEs were added to the Canadian Environmental Protection Act (CEPA) as Schedule 1 Toxic Substances in 2006.

Most of the prevalent PBDE homologue groups are listed in Annex A of the Stockholm Convention as Products for Elimination; the tetra, penta, hexa, and hepta congeners were added in 2009, with decaBDE added in 2017.

In Nov 2023, the US EPA announced new requirements for workplace safety protections and restrictions of water releases for remaining critical decaBDE uses such as in flame resistant materials for the nuclear power, aerospace, and automotive industries. These restrictions may increase future environmental testing requirements for decaBDE in the US.

Table 3. Canadian PBDE Environmental Guidelines (2013)

| BDE Parameters | Water 1,2 | Sediment 1 | Fish Tissue 1 | Wildlife Tissue 1,3 | Bird Eggs |

| ng/L | ng/g dwt | ng/g wwt | ng/g wwt | ng/g wwt | |

| triBDE (total) | 46 | 44 | 120 | - | - |

| tetraBDE (total) | 24 | 39 | 88 | 44 | - |

| pentaBDE(total) | 0.2 | 0.4 | 1.0 | 3(13 avian) | 29 |

| pentaBDE(BDE-99) | 4 | 0.4 | 1.0 | 3 | - |

| pentaBDE(BDE-100) | 0.2 | 0.4 | 1.0 | - | - |

| hexaBDE(total) | - | 440 | 420 | 4 | |

| heptaBDE (total) | 120 | - | - | 64 | - |

| octaBDE (total) | 17 | 5600 | - | 63 | - |

| nonaBDE (total) | 17 | - | - | 78 | |

| decaBDE (BDE-209) | - | 19 | - | 9 |

Stockholm Convention Annex A (Products for Elimination) shown in RED

dwt = dry weight wwt = wet weight

1 Adopted by Alberta (Environmental Quality Guidelines for Alberta Surface Waters, 2018)

2 Fresh and marine waters

3 Mammalian unless otherwise specified

ALS Method for PBDE Testing

The ALS Burlington laboratory has been testing for PBDEs since 2007 by US EPA Method 1614A (GC/HRMS – with Isotope Dilution). The analysis of PBDEs to meet low-level environmental criteria remains challenging. With molecular weight of 960 Daltons, decaBDE approaches the upper limits of gas chromatography, and optimized GC injector and column conditions are required to ensure reliable method performance. In addition to testing of soil/sediment, tissue/biota, and discrete water samples, ALS also offers ultra-trace level testing of pristine marine and freshwater environments using Semi-Permeable Membrane Devices (SPMDs), which can be deployed in-situ for long periods to enable detection, with application of modeling equations to estimate time-weighted ambient concentrations.

Sample Collection Details and Testing Options

Table 4 provides the comprehensive listing of PBDEs quantified by ALS Burlington’s EPA 1614A method, which ensures that all congeners with significant environmental presence are included in reported PBDE test results. Analysis for important Polybrominated Biphenyl congeners (PBBs) and other related brominated flame retardants may be added to PBDE tests, as shown in Table 5.

Table 4. Targeted BDE Congeners (EPA 1614A)

| Target PBDE Analytes | Bromination Level | Target PBDE Analytes | Bromination Level | |

| BDE-8/BDE-11 | di | BDE-119/BDE-120 | penta | |

| BDE-15 | BDE-126 | |||

| BDE-17/BDE-25 | tri | BDE-128 | hexa | |

| BDE-28/BDE-33 | BDE-138/BDE-166 | |||

| BDE-32 | BDE-140 | |||

| BDE-35 | BDE-153 | |||

| BDE-37 | BDE-154 | |||

| BDE-47 | tetra | BDE-155 | ||

| BDE-49 | BDE-156 | |||

| BDE-51 | BDE-181 | hepta | ||

| BDE-66 | BDE-183 | |||

| BDE-71 | BDE-184 | |||

| BDE-75 | BDE-190 | |||

| BDE-77 | BDE-191 | |||

| BDE-79 | BDE-196 | octa | ||

| BDE-83 | penta | BDE-197 | ||

| BDE-85 | BDE-203 | |||

| BDE-99 | BDE-206 | nona | ||

| BDE-100 | BDE-207 | |||

| BDE-105 | BDE-208 | |||

| BDE-118 | BDE-209 | deca |

Table 5. Other Brominated Flame Retardant Analytes

| Other Brominated Analytes | Abbreviated Name | Bromination Level |

| Hexabromobenzene | HBB | hexa |

| Pentabromoethylbenzene | PBEB | penta |

| Polybrominated Biphenyl-52 | PBB-52 | tetra |

| Polybrominated Biphenyl-101 | PBB-101 | penta |

| Polybrominated Biphenyl-153 | PBB-153 | hexa |

| Polybrominated Biphenyl-180 | PBB-180 | hepta |

| Polybrominated Biphenyl-194 | PBB-194 | octa |

| Polybrominated Biphenyl-206 | PBB-206 | nona |

| Polybrominated Biphenyl-209 | PBB-209 | deca |

| Decabromodiphenylethane | DBDPE | deca |

Sample collection details are summarized in Table 6. Although they are generally highly stable, PBDEs and PBBs are susceptible to photolytic debromination when exposed to UV light, so samples should be protected from light during sampling and in transport to the lab. Amber glass containers are required for waters, and are recommended for soils, sediments, and tissue/biota samples. The recommended maximum hold time from sampling to analysis for these tests is one year.

Table 6. Sampling Details for Brominated Flame Retardants

| Matrix | Sample Containers & Preservation | Hold Times |

| Water | 2 X 1 L amber glass (Sodium Thiosulfate if chlorinated) | 1 year |

| Soil / Sediment | 250 mL amber glass | 1 year |

| Tissue / Biota | 250 mL amber glass | 1 year |

ALS Burlington currently holds ISO 17025 accreditation from CALA for the analysis of PBDEs, HBB, PBEB, and DBDPE in water, soil/sediment, and tissue/biota. Please refer to the ALS Burlington Scope of Accreditation for current accreditation status.

Please contact your ALS Project Manager with any questions, or to arrange for sampling supplies.