What to Look for in an Extractables & Leachables Testing Partner

"Drug product containers and closures shall not be reactive, additive, or absorptive so as to alter the safety, identity, strength, quality or purity of the drug beyond the official or established requirements."

- US FDA, Code of Federal Regulations (1)

You can have all the confidence in the world in your pharmaceutical product or medical device, but it’s critically important to keep in mind that your product doesn’t exist in isolation. Everything it contacts – from containers, closures and delivery devices to the functional components of manufacturing equipment such as single-use systems – contains compounds that could migrate into your product, affecting its safety, stability, efficacy, and/or quality.

True confidence in your product requires identifying and quantifying these compounds, known as extractables & leachables (E&L), to discover whether any are present in quantities sufficient to pose a risk to the product or consumers.

The difference between extractables and leachables

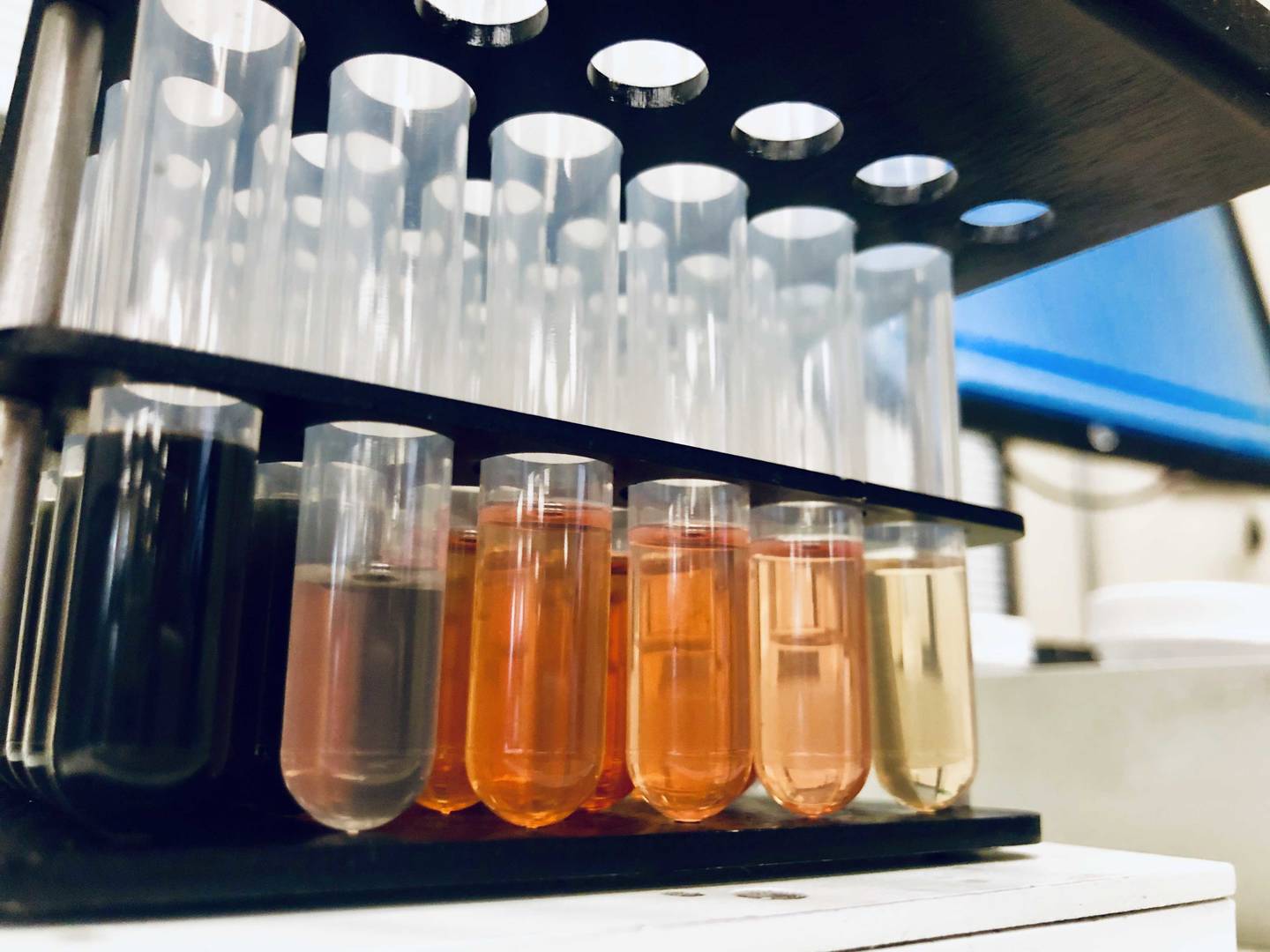

Extractables are chemical species that can be released from the surfaces of components used in the manufacture and storage of drug products under laboratory conditions, such as accelerated or exaggerated temperatures, solvents or surface exposure. Extractables testing creates worst-case scenario conditions in the lab to determine the broad set of chemicals released from packaging under forced extraction.

Leachables are chemical species that are released from the surfaces of such components under conditions of normal use. Leachables testing analyses the product itself to determine and quantify chemicals released from the surfaces of components used in manufacturing and packaging components under typical storage conditions.

In essence, extractables studies test the materials, and leachables studies test the product. One note is that while the chemicals identified as leachables will generally form a subset of the extractables, a leachables study may also identify chemical species that were not observed in an extractables study. To accurately assess your pharmaceutical product, both types of tests must be performed.

The challenges of E&L compliance

Testing for E&L is about more than thoroughly understanding the components that may pose a risk to your product: when applying for the authorisation to market a drug product, manufacturers must submit scientific studies to regulatory agencies like the US Food and Drug Administration (FDA) and European Medicines Agency (EMA), demonstrating that the containers, closures and equipment used to manufacture the product have not altered its purity.

On the journey to bring your product to market, the challenges related to E&L testing and compliance can be daunting, and you will find yourself faced with questions about aspects of the process, such as:

-

How do I handle the diversity of sample types and matrices?

-

Do I have the right equipment types and techniques to yield accurate results?

-

Can I accurately interpret and report on contaminants and compounds?

-

Will I understand the applicable regulatory requirements and expectations?

To address these challenges, manufacturers often seek an E&L testing partner to conduct the studies and help them navigate compliance demands, including providing the necessary documentation. The right E&L testing partner can provide you with peace of mind in bringing your product to market and help you meet the rigorous testing demands required for approval by regulatory agencies.

Seeking an E&L testing partner is highly advisable, but it can confront you with another critical question: with so much at stake and so many companies offering E&L testing services, how do you choose the right one to help you meet your specific testing and compliance needs? Here are our recommendations for the most important considerations in choosing your E&L testing partner:

Technical expertise and experience

Given the complexity of E&L testing, it’s important to partner with a team of scientific experts highly experienced in conducting E&L studies in state-of-the-art laboratories backed by a company with a strong track record of providing accurate and reliable testing services.

As a global testing leader, ALS has a professional team of 45 scientists devoted solely to E&L studies. We have 15 years of experience in E&L and have managed over 300 product testing projects for companies around the world. The uncompromising commitment of our team of experts to ensuring the safety and compliance of your products through rigorous E&L testing, advanced quality control and robust data management systems, makes us a dependable partner for any E&L testing project or challenge.

Comprehensive testing methods

Not all testing laboratories are the same. It is important that your testing partner’s labs are fully equipped with the latest state-of-the-art analytical equipment required for E&L testing.

Because of the diversity of sample types and analytical challenges unique to E&L testing, your partner should use a variety of advanced equipment and techniques to provide both quantitative and qualitative E&L studies, including organic analysis by gas chromatography (GC), mass spectrometry (MS), high-performance liquid chromatography (HPLC), and liquid chromatography with high resolution mass spectrometer (LC-HRMS).

At ALS, we use all these analytical technologies and more. We are a leader in conducting elemental analysis by inductively coupled plasma mass spectrometry (ICP-MS). We also have equipment for spectroscopy, pH and ion chromatography. This use of multiple technologies and testing approaches enables us to provide services tailored to your drug product and packaging types.

When you partner with us, you can be confident that we will recommend the right procedures for your needs, and that we conduct our studies following cGMP-compliant procedures, meeting the requirements for marketing authorization and delivering dependable results and accurate documentation.

Strong understanding of regulatory demands

On the journey to bring your product to market, the task of understanding the intricate and dynamic web of regulations governing E&L is essential and leaves little room for error. It is critically important to choose a partner that is constantly refining its approaches and practices to meet the vast and ever-evolving regulatory landscape.

While there is currently no single global regulated method prescribed for analyzing E&L, regulatory guidelines have been published regarding the risks of E&L and the need for product impact assessments in both the US and Europe, including the US FDA’s Code of Federal Regulations (CFR) Title 21 and Chemistry, Manufacturing and Controls (CMC) documentation guidance on Container Closure Systems for Packaging Human Drugs and Biologics.

More recently, the United States Pharmacopeia (USP) introduced general chapters on the assessment of E&L associated with pharmaceutical packaging and delivery systems. Likewise, the European Medicines Agency (EMA) issued its Guideline on Plastic Immediate Packaging Materials and other guidelines that establish requirements for monitoring impurities associated with packaging materials in drug products. Additionally, Product Quality Research Institute (PQRI) a non-profit consortium of organizations with leaders/members from regulatory agencies, standard setting bodies, industry and academia, provides recommendations on E&L testing that have been adopted by regulators globally.

At ALS, our testing approach is driven by our clients’ compliance needs. Our capabilities adhere to guidelines/normative references including those established by the FDA CFR, USP, PQRI, EMA and others. We maintain an active knowledge of relevant regulations and provide our clients with comprehensive compliance support, including timely regulatory filings related to E&L testing data.

Dedicated client support

A key concern in choosing your E&L testing partner should be whether the company has a reputation for providing responsive and transparent client service. You should be able to receive a price quote that includes an honest estimate of costs and potential additional charges associated with your project. Your testing partner should be able to explain what tests are recommended and why, as well as inform you of a probable turnaround time that considers your project timeline.

ALS places an unwavering emphasis on customer care. As a global leader in providing professional and reliable testing services, we have a reputation for going above and beyond in serving our clients. We provide fast turnaround times and full transparency for every aspect of your project.

Right solutions. Right partner.

We know you have many options in choosing an E&L testing services provider and hope you will make your decision carefully based on the criteria discussed in this article. We would be delighted to have an opportunity to discuss your project and become a trusted partner in your quest for quality, safety, and regulatory compliance. By working together with you closely and leveraging our expertise and resources, we can successfully navigate the complexities associated with your E&L testing, contributing to your success in the market and enabling you to help patients and consumers experience the benefits of your product.

Contact us today at asnvm.sales@alsglobal.com

About ALS Limited

A global leader in testing, ALS provides comprehensive testing solutions to clients in a wide range of industries around the world. Using state-of-the-art technologies and innovative methodologies, our dedicated international teams deliver highest-quality testing services and personalized solutions supported by local expertise. We help our clients leverage the power of data-driven insights for a safer and healthier world.

References

1. 21 CFR 211.94(a)