EnviroMail 08 USA

Standard 61 Certifications

In order to adequately certify water system components to ANSI/ NSF Standard 61, it is best to utilize a certifier accredited through The American National Standards Institute (ANSI) and the Standards Council of Canada (SCC). Product certifications by ANSI/SCC accredited certifiers are required to be equally accepted by regulators, specifiers and manufacturers.

By “leveling the playing field” through a standardization of accreditation, quality control issues are no longer a driving force for specifiers and regulators, and their focus for selecting a third-party certifier can be based on those that best align with their service requirements and price point.

Currently, forty-nine states have legislation, regulations, or policies requiring drinking water system components to comply with, or be certified to, Standard 61. For more information on choice certifiers and products certified, please review the Product Listings Search.THE NSF/ANSI 61 CERTIFICATION PROCESS IS EXTENSIVE AND THOROUGH

Standard 61 covers water system component that have drinking water contact. Certification by Standard 61 assures the end-user that products have been thoroughly tested and they do not leach harmful contaminants into drinking water. The rigorous process involves multiple checks and balances, including complete product information disclosure, a thorough engineering review, chemical leachate testing, and an audit of all manufacturing facilities producing the certified product. All requirements must be satisfied before a manufacturer can place the certification mark and claim NSF/ANSI Standard 61 certification.

PRODUCT INFORMATION AND FORMULATION DISCLOSURE

A manufacturer applying for certification first submits precise information about the design and field use of each product. Product information covers many details, which include engineering schematics, product literature, parts lists, formulation details, bill of materials, and information about the manufacturing process. Products are reviewed and certified at each manufacturing facility. Certification at one plant does not authorize the manufacturer to use the certification mark on the same product at other facilities.

The disclosure of design details and formulation information is required for all water contact materials. The manufacturer must disclose the trade name and source of supply for each wetted material or ingredient used in the product. Manufacturers must also disclose all specialized process steps to determine if the step has a potential health effect impact.

Function and field use conditions of the product are disclosed to ensure a thorough evaluation process and an accurate certification decision. Product function can impact the type of evaluation the product receives. For example, coatings undergo a different evaluation process depending on whether they are applied to a pipe, valve or storage tank.

ALS-Truesdail staff authored the most recent rewrite of Section 3.2 - Information and Formulation Requirements, 3.3 - Identification of Analytes, and 3.3.1 - Formulation-dependent Analysis Selection in ANSI/NSF Standard 61.

COMPREHENSIVE ENGINEERING AND CHEMICAL REVIEW

In order to provide the required comprehensive engineering and chemical review to select the appropriate test samples, ensure your certifying laboratory is equipped with a team of experts. Relevant attributes of the product are evaluated during the review, which includes how the product is used in a plumbing system to the potential for each material to contribute leachates into drinking water. This review includes a chemical by chemical assessment for each material used to determine the potential for each component to contribute a contaminant to drinking water. For products that include variations within a family, (e.g. different formulations, models, or sizes), the engineer determines which product within the family will require testing. When a family of products share similar ingredients, materials, processes, and field end uses; a “worst-case” testing scenarios can often be established, where a single test can be representative of a range of products.

Once the test samples have been selected, the technical team summarizes the required testing in a customized plan, which is used to direct laboratory testing of the product. For Standard 61, the test plan includes a complete set of directions to the laboratory regarding required analyses, exposure water temperature, exposure duration, normalization factors and other details necessary to complete the chemical testing of the product. This thorough review and testing ensures the product is tested to all applicable health effects requirements.

MANUFACTURING SITE AUDIT

Each facility seeking to manufacture a certified product must undergo an initial and annual audit. The certifying auditor visits the facility and performs a comprehensive inspection. An audit typically includes a walk-through of the production area as well as a review of the facility’s production processes and quality control program. The auditor looks to identify sources of potential product contamination and reviews the manufacturer’s record system. Additionally, the auditor will compare the facility’s records for product composition and material sources against the official record of materials evaluated during the product’s engineering review. Any discrepancies between this document and the actual production records at the facility must be resolved prior to certification of the product. Formulary and supply chain differences have the potential to have an impact on public health. At the conclusion of the audit, the certifying auditor completes an audit report summarizing the results and identifies any areas of non-compliance. All non-compliances must be resolved prior to certification.CHEMICAL LEACHATE TESTING

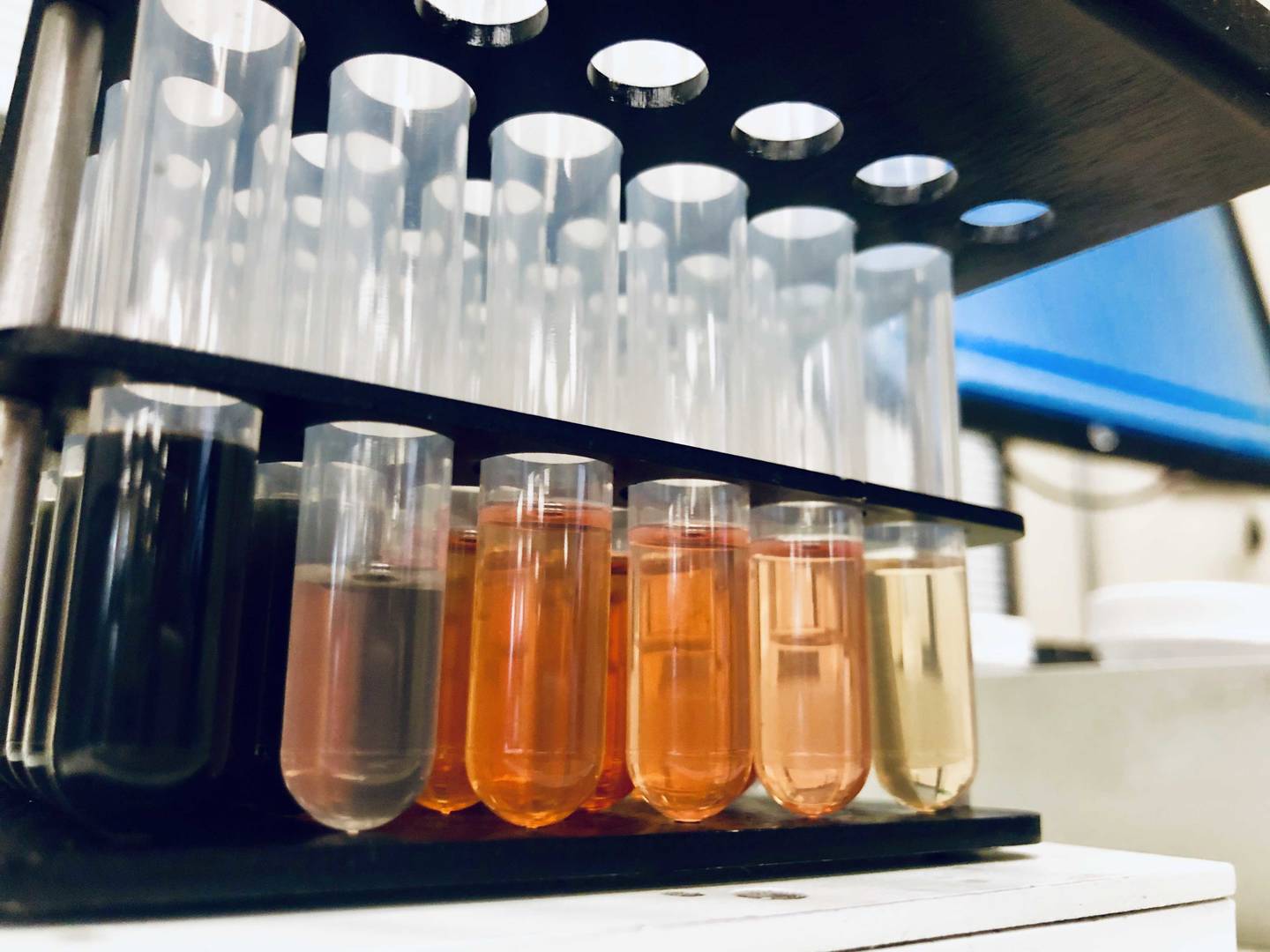

After the engineering and chemical review is complete, the samples are requested from the manufacturer or collected in person during the onsite audit. Once the samples arrive in the laboratory, the customized test plan directs the laboratory on how the product will be tested. Products are exposed to the test waters made of various chemistries in a manner that most closely matches their end-use once installed in a plumbing system. The samples then undergo a sequence of water changes, with the length of exposure lasting one to 90 days depending on the product. At the end of the exposure sequence, the water is collected for analysis. To ensure high quality, product exposures also include a control sample and method blank, which are used for background subtraction.

Analytical testing of the leachate water is the next step of the testing process. The water samples are prepared and preserved prior to analytical testing. Standard testing includes analysis for regulated and non-regulated metals, as well as a wide range of semi-volatile and volatile organic compounds. Analytical instrumentation includes utilization of inductively coupled plasma mass spectroscopy (ICPMS), gas chromatography with mass spectroscopy (GC-MS), highperformance liquid chromatography (HPLC), liquid chromatography with mass spectroscopy (LC-MS), and other quantitative analytical instrumentation. Contaminants are identified quantitatively using calibration standards, or by comparison against the NIST spectral library of over 100,000 individual compounds. The level of each compound detected in the leachate water is quantified and then summarized in a test report. Following peer review and final sign off by chemistry lab personnel, the test report is sent to engineers and toxicologists for final evaluation.

TOXICOLOGY REVIEW OF LEACHED CHEMICALS

The next step in the evaluation is to “normalize” the test results to accurately reflect field use conditions of the product. The result of this calculation is intended to reflect the concentration in the water when a person drinks from the tap.

ALS-Truesdail staff were instrumental in establishing many of the normalization parameters currently published in NSF/ANSI 61, including the table in Section 5, which establishes the model to evaluate various sizes of tanks.

After the leachate concentrations are adjusted to reflect “at-the-tap” concentrations, they are compared to the pass/fail criteria as listed in the standard. The use of pass/fail criteria are based on a hierarchy described in Annex A. The pass/fail criteria set by the U.S. EPA or Health Canada are preferentially used when available. In the absence of U.S. EPA or Health Canada criteria, risk assessments published by other entities such as the World Health Organization (WHO) or the International Programme on Chemical Safety may be used. Alternately, with sufficient toxicological data, pass/fail levels can be set by toxicologists from the various certifying organizations. External peer review by the Health Advisory Board following approval by the Joint Peer Review Committee is required prior to incorporation into the Standard. The Joint Peer Review Committee is made up of representatives of all of the ANSI approved certifiers.

The staff toxicologist at ALS-Truesdail has developed hundreds of the risk values reported in NSF/ANSI 61, has peer reviewed hundreds of other substances, and was instrumental in the development of the Health Advisory Board and the Joint Peer Review Committee.

For compounds that do not have criteria and are identified at very low levels, the use of the Threshold of Evaluation Level can be used prior to having a complete risk assessment completed for the compound. After comparing the level of each compound detected against the appropriate criterion, the product may be recommended for certification provided there was successful completion of the audit and all other requirements are met.