EnviroMail 60 Canada

Global Best Practices for High Quality Analysis of Waters for Trace Metals & Mercury

This EnviroMail highlights important practices for the collection of water samples for analysis of trace metals and mercury which can greatly improve the quality of test results, preventing false positives and false negatives, while also improving the efficiency of field sampling events.

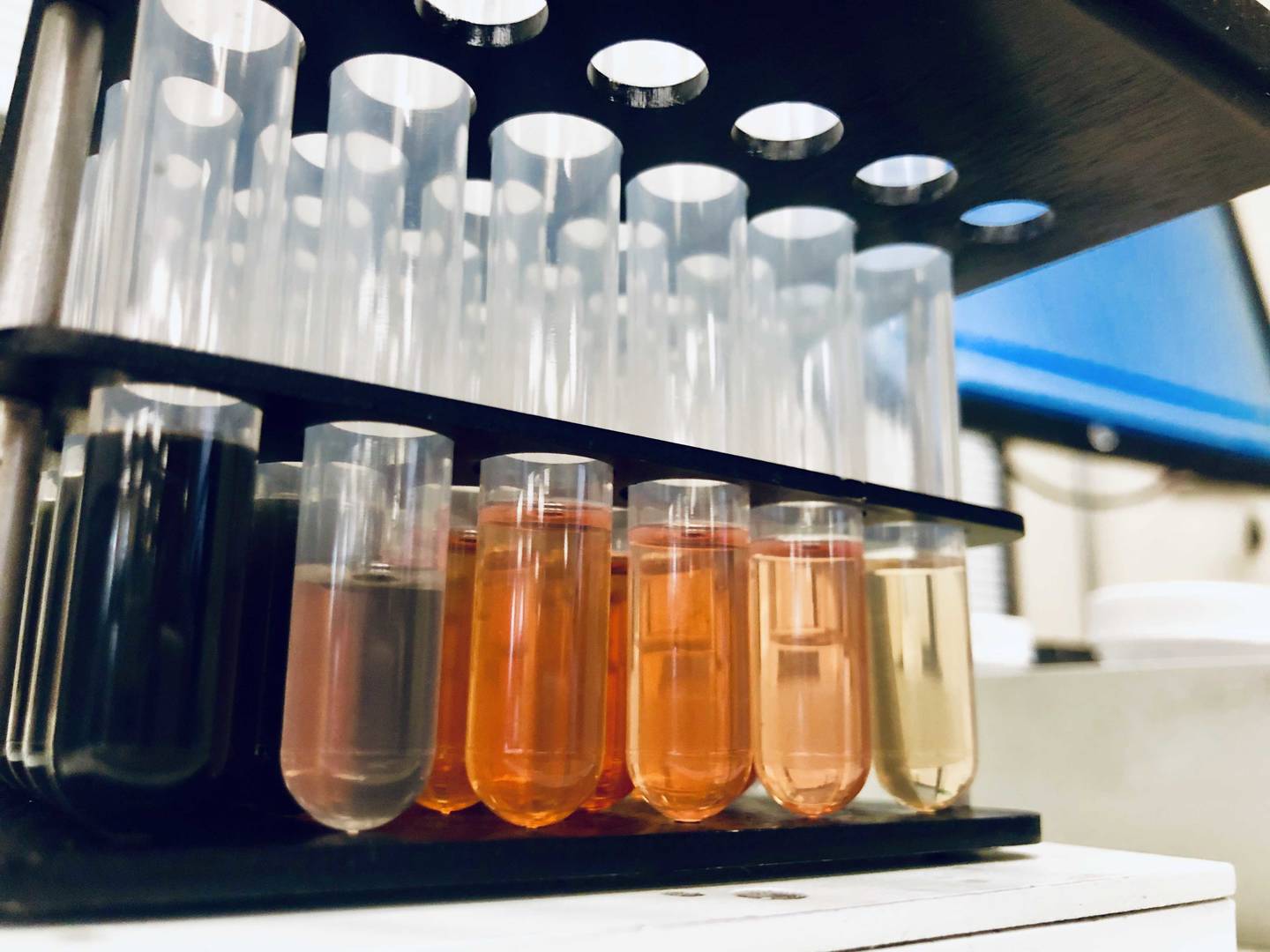

Ultra-Clean Sample Bottles for Trace Metals

One of the most crucial aspects of trace metals analysis is the quality of the sample container. All plastics will leach trace amounts of common metals when exposed to nitric acid preservative, and for many metallic elements, the quality of the sample container is the most limiting factor where trace-level detection limits (DLs) are needed.

ALS recently conducted a global study of sample containers to identify the best and cleanest bottles used by any of our trace metals labs around the world, evaluating over forty sample containers sourced from seven countries. We conducted ultra-trace metals testing down to 1/10th of the ALS Canada trace metals DLs, with testing done at two ALS labs that offer some of the lowest commercially available metals DLs in the world – in Vancouver and Lulea, Sweden. Testing protocols included short and long-term leaching studies with acidified samples as well as suitability testing for use with pre-charged concentrated nitric acid, which is a common practice for metals testing in some regions, including Ontario. Our studies confirmed that pre-charging any plastic containers with concentrated nitric acid tends to liberate higher concentrations of many common elements from the container walls (e.g., chromium), which can limit the levels to which reliable DLs can be provided.

By using sample containers selected specifically for their suitability and cleanliness for trace metals, in conjunction with rigorous bottle proofing protocols, ALS can offer lower DLs with confidence that false positives will not occur due to contamination from sample bottles. Our container selection and proofing protocols are designed to ensure that pre-rinsing with sample is never required or even recommended for any tests we offer.

Preservation of Metals with Nitric Acid

Sample preservation is used with many tests to ensure test analytes are stabilized, so measured sample concentrations represent the sample condition at time of collection. For trace metals, preservation with nitric acid reduces sample pH to < 2 to ensure solubility of metals prior to analysis, preventing sorption to container walls or precipitation as metal oxides or hydroxides.

Traditionally, preservation for metals has been conducted in the field, but recently there has been recognition that lab preservation of metals samples is preferable for numerous reasons. In fact, the US EPA has recommended lab preservation as the best practice for sampling of metals in water for at least 35 years (Method 200.2, 1989). Among other benefits, lab preservation avoids restrictions with Transportation of Dangerous Goods (TDG), and avoids contamination risks and hazards that can occur when handling concentrated acids in the field.

Lab Preservation – Best Practice for Trace Metals Sampling

ALS Canada has offered lab preservation for metals since 2017. We now recommend lab preservation as the best practice for trace metals analysis of waters to maximize data quality and to improve sampling logistics. Lab preservation is recommended or endorsed by the US EPA, CCME, and BC ENV, but is not yet authorized in Ontario by MECP. Requirements for lab preservation of metals are that samples must be preserved with nitric acid in their original sampling container, with no sub-sampling or analysis permitted until completion of a 16-hour equilibration period, to ensure full solubilization of metals prior to analysis. Because of the 16-hour equilibration requirement, lab preservation is unsuitable for same-day analysis requirements. Hold times are the same as for field preservation (6 months from time of sampling), as long as preservation occurs within 14 days of sampling.

Lab preservation is suitable for total metals and for field-filtered dissolved metals. In all cases, field filtration is required to provide defensible test results for dissolved metals (refer to section on field filtration for more details).

Lab preservation offers data quality improvements over other preservation options for several reasons:

- Lower and more reliable detection limits can be offered - especially for chromium - versus containers pre-charged with nitric acid, due to leaching of metals over time from plastics by concentrated acid. Low-level chromium DLs are useful to screen for aquatic life risks due to hexavalent chromium.

- Contamination risks are minimized by reducing physical handling in the field, and by collecting samples quickly with minimal exposure to dust (e.g., at windy mine sites).

- Eliminates potential cross-contamination of nutrient samples with nitrate from nitric acid.

- Addition of acid preservatives in the lab utilizes high-grade nitric acid, tested daily before use for purity control, and added to samples in a clean, controlled, dust-free environment.

Where the absolute lowest possible DLs are required, ALS recommends lab preservation with specially prepared acid-cleaned bottles (ACBs), which we provide for specific specialty test codes for ultra-trace level metals.

Field Preservation for Metals: Applications and Precautions

ALS also offers two field preservation options for metals in special circumstances, such as in Ontario, where lab preservation is not approved, or for same-day rush testing needs.

The use of pre-charged sample containers for metals in water has become standard practice in Ontario. This is an effective and easy-to-use approach, however as described above, this limits our ability to offer testing for trace-level DLs for some metals (e.g., chromium below ~ 0.5 µg/L).

Field preservation can also be achieved using small vials of 18% wt/wt nitric acid which are added to samples in the field. This is a good option where same-day analysis is required (to avoid the 16-hour equilibration time for lab preservation), but requires additional precautions to reduce contamination risks for metals or nitrate during sampling.

Mercury Sampling with Pre-Charged Glass Vials

Best practice for collection of water samples for testing of mercury is quite different from other metals. Because dissolved mercury can readily sorb to plastics (especially at low or trace levels), all Canadian jurisdictions now require water samples for mercury testing to be collected in glass or PTFE sample containers. Unlike other metals, dissolved mercury is stabilized much more effectively with hydrochloric acid than with nitric acid, because mercury tends to form the stable anion [HgCl4]2- in the presence of HCl, which helps to prevent sorption to container walls.

Lab preservation is also possible for mercury, but the equilibration period at the lab after preservation is longer than for other metals, at 24 hours versus 16 hours, which often adds an additional day to turnaround times. Water samples for routine-level mercury testing are normally sampled in 40 mL glass vials with tightly-sealed leakproof PTFE-lined septa caps, which virtually eliminates leaks. ALS recommends pre-charged mercury vials for routine-level testing because this practice expedites turnaround times with no significant disadvantages.

Field Filtration for Dissolved Metals and Mercury

Most environmental practitioners know that field filtration is considered the best practice for dissolved metals testing, but some are unaware of the causes and potential severity of consequences of delayed filtration. Dissolved metals in water exist in complex equilibria, which are controlled by many physical and chemical factors such as redox conditions, pH, and temperature, which can trigger dramatic changes to dissolved metals concentrations due to precipitation, co-precipitation, sorption, or dissolution. These factors can cause severe negative or positive bias to dissolved metals or mercury concentrations.

The most common pitfall with delayed filtration of dissolved metals is caused by precipitation of iron oxides and the associated co-precipitation of other metals. This happens because ferrous iron (Fe2+) is relatively water soluble (potentially > 100 mg/L), whereas ferric iron (Fe3+) is practically insoluble under normal environmental conditions (generally < 10 μg/L). Ferrous iron is common and stable in anoxic waters (e.g., many groundwaters), but after exposure to air, oxidation to ferric iron can occur rapidly, sometimes in as little as five to ten minutes (oxidation rate increases substantially with higher pH). When iron precipitation occurs, other metals can co-precipitate, causing substantial reductions to the overall dissolved metals composition of the sample. This is a well-known phenomenon, and precipitation of iron under these circumstances is expected, but co-precipitation of other metals is much less understood.

The only way to ensure that dissolved metals and mercury test results will accurately represent conditions at time of sampling is to conduct filtration in the field immediately after sample collection. Most Canadian regulatory jurisdictions (including CCME, BC ENV, and ON MECP) now require field filtration for sampling of dissolved metals. Please refer to EnviroMail 6 for more information about best practices for dissolved metals.

Field filtration of dissolved metals by syringe filter

Please consult your ALS Canada Project Manager for additional guidance, or to arrange for suitable sampling containers and preservatives for your next trace metals sampling project.