-

Procurar

Procurar

Search

-

português

português

-

Iniciar sessão

Iniciar sessão

ALS Solutions

A ALS Solutions dá-lhe acesso online à sua amostra e informação analítica a partir de qualquer lugar.

Iniciar sessãoGeochemistry WebtrieveTM

Obtenha resultados e acompanhe o progresso das amostras em tempo real com o acesso a produtos digitais em destaque, como o CoreViewer™ e o ALS QCPro™.

Iniciar sessão

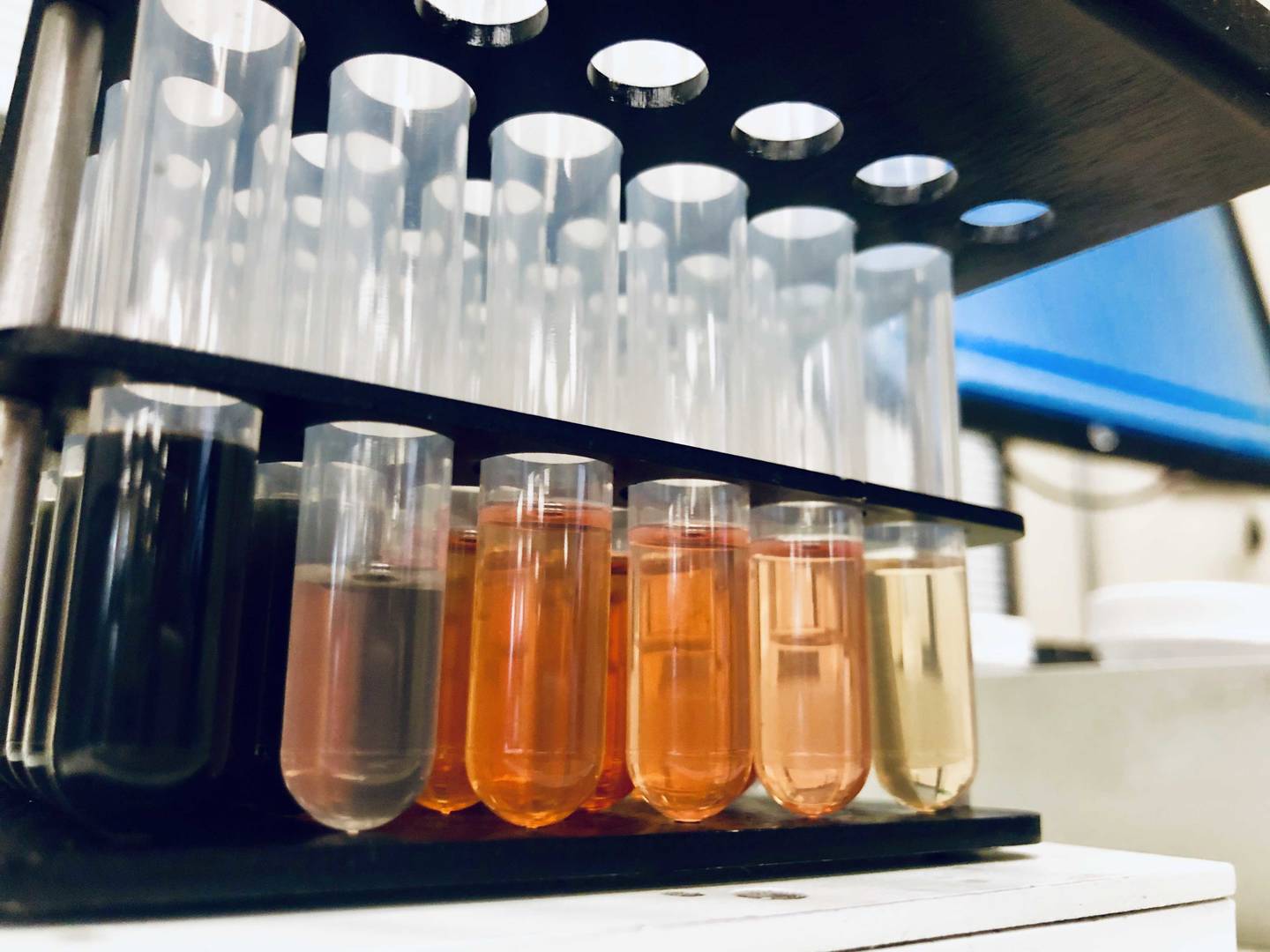

Tribology 360

Esta prática aplicação permite aos clientes acompanhar de perto os relatórios de análise de petróleo em curso e em tempo real.

Iniciar sessão